- africain

- albanais

- arabe

- biélorusse

- bengali

- tchèque

- danois

- Néerlandais

- Anglais

- finlandais

- Français

- galicien

- Allemand

- grec

- hébreu

- hongrois

- indonésien

- irlandais

- italien

- japonais

- javanais

- kazakh

- Khmer

- Rwandais

- coréen

- Kirghize

- Travail

- latin

- letton

- lituanien

- malais

- maltais

- mongol

- Birmanie

- norvégien

- persan

- polonais

- portugais

- roumain

- russe

- serbe

- slovaque

- Espagnol

- suédois

- Tagalog

- thaïlandais

- turc

- ukrainien

- vietnamien

- gallois

When it comes to pigments used in the manufacturing of paints, coatings, and other industrial products, lithopone and titanium dioxide are two of the most important compounds that dominate the market. While titanium dioxide is well-known for its brilliant whiteness and durability, lithopone and titanium dioxide together offer a unique combination of properties that make them a preferred choice for various applications.

Lithopone and titanium dioxide are both used extensively in the production of white pigments. Lithopone is often used as an affordable alternative to titanium dioxide, especially in applications where the highest level of opacity is not required. On the other hand, titanium dioxide excels in areas that require superior whiteness, light stability, and overall performance. By blending lithopone and titanium dioxide, manufacturers are able to produce pigments with desirable characteristics at a more cost-effective price point.

This powerful combination also plays a significant role in the development of high-quality paints, plastics, rubber, and paper. By understanding how lithopone and titanium dioxide interact, industries can make informed decisions about which pigment best suits their specific needs, offering them both quality and cost efficiency.

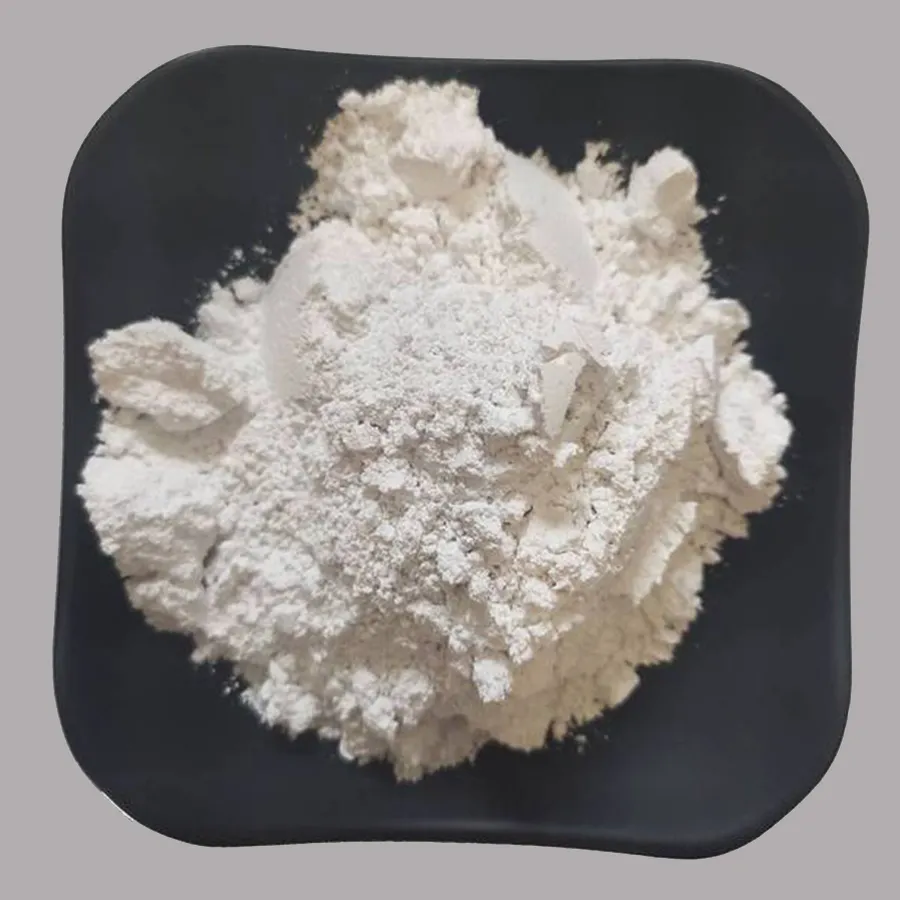

Lithopone Pigment

Lithopone pigment is one of the most versatile and economical pigments used in the industry. It is a mixture of zinc sulfide and barium sulfate that provides a brilliant white color. It is primarily used as a white pigment in various applications such as paints, coatings, and plastics, offering excellent opacity at a lower cost compared to other white pigments like titanium dioxide.

Lithopone pigment is often favored in situations where the highest level of durability or UV resistance is not critical. Its primary strength lies in its ability to offer good hiding power, making it ideal for use in low-cost paints or coatings. For example, it is commonly used in decorative paints, wall coatings, and industrial applications. Additionally, lithopone pigment has applications in the rubber industry, where it is used to improve the appearance and physical properties of rubber products.

One of the key advantages of lithopone pigment is its compatibility with other materials. It can be easily mixed with titanium dioxide, enhancing the overall performance of the pigment mixture, particularly in terms of opacity and brightness. When choosing a pigment, manufacturers must consider the specific performance characteristics required by their applications, and lithopone pigment often fits the bill when cost-efficiency is a top priority.

Lithopone Manufacturers

Finding reliable lithopone manufacturers is key to ensuring that you receive high-quality lithopone pigment that meets your production standards. Lithopone manufacturers specialize in the production of this important pigment, and they play a critical role in delivering consistent quality to meet the growing demand from industries such as construction, automotive, and consumer goods.

When selecting lithopone manufacturers, it is important to consider factors such as production capacity, quality control processes, and the availability of customization options. Reputable lithopone manufacturers focus on providing a consistent and high-quality product, ensuring that their customers receive lithopone pigment that performs well in a wide range of applications.

In addition, many lithopone manufacturers offer technical support to help businesses optimize the use of lithopone pigment in their formulations, enhancing the overall efficiency of production processes. Whether you need lithopone pigment for paints, coatings, or other industrial applications, working with experienced manufacturers will ensure that you get the best quality product at competitive prices.

Application of Lithopone

The application of lithopone is vast and widespread across multiple industries due to its excellent opacity, good durability, and cost-effectiveness. One of the main applications of lithopone is in the production of paints and coatings, where it is used as a white pigment to provide excellent coverage and a smooth finish. It is commonly found in exterior coatings, wall paints, and even in automotive coatings, where its relatively lower cost compared to titanium dioxide makes it an attractive alternative for certain formulations.

Beyond the paint industry, the application of lithopone extends to the manufacturing of plastics and rubber. In these industries, lithopone pigment is used to enhance the appearance of products while contributing to their overall durability and functionality. It is often added to products such as plastic pipes, automotive parts, and rubber seals, helping them maintain a clean, white finish throughout their lifespan.

In addition, the application of lithopone in the paper industry is gaining momentum. It is used as a filler in paper production to improve its whiteness and opacity. This makes lithopone pigment a key ingredient in producing high-quality printing papers and cardboards, where the visual appeal and print quality are critical.

The versatility of lithopone ensures that its applications are not limited to a single industry. With its ability to mix well with other pigments, it also finds use in industries such as textiles, ceramics, and cosmetics, where it helps create bright, durable products at an affordable cost.

Lithopone Pigment FAQs

What is lithopone pigment?

Lithopone pigment is a white pigment made from a combination of zinc sulfide and barium sulfate. It is commonly used in paints, coatings, plastics, and rubber products for its excellent opacity and cost-effectiveness.

What are the main uses of lithopone pigment?

The main uses of lithopone pigment are in paints and coatings, plastics, rubber products, and paper production. It is known for providing good hiding power and a durable finish.

How does lithopone compare to titanium dioxide?

While titanium dioxide is known for its superior whiteness and UV resistance, lithopone offers a more affordable option for applications where the highest level of opacity is not necessary. It is often used as a substitute for titanium dioxide in lower-cost products.

Where can I find reliable lithopone manufacturers?

Reputable lithopone manufacturers can be found through industry directories, trade fairs, and online platforms. It’s important to consider factors such as product quality, production capacity, and customer reviews when choosing a manufacturer.

What industries benefit from lithopone?

Industries such as construction, automotive, consumer goods, paper production, and coatings all benefit from the use of lithopone due to its excellent opacity, durability, and cost-effectiveness.

Nouvelles connexes