- africain

- albanais

- arabe

- biélorusse

- bengali

- tchèque

- danois

- Néerlandais

- Anglais

- finlandais

- Français

- galicien

- Allemand

- grec

- hébreu

- hongrois

- indonésien

- irlandais

- italien

- japonais

- javanais

- kazakh

- Khmer

- Rwandais

- coréen

- Kirghize

- Travail

- latin

- letton

- lituanien

- malais

- maltais

- mongol

- Birmanie

- norvégien

- persan

- polonais

- portugais

- roumain

- russe

- serbe

- slovaque

- Espagnol

- suédois

- Tagalog

- thaïlandais

- turc

- ukrainien

- vietnamien

- gallois

Bauxite mines for sale are becoming an increasingly important resource in the global aluminium industry. With the demand for aluminium continuing to rise due to its versatile properties in sectors like construction, transportation, and electronics, the need for high-quality bauxite is higher than ever. Purchasing a bauxite mine for sale presents an opportunity for investors and companies to secure a steady supply of this valuable raw material.

When looking for bauxite mines for sale, it is essential to consider several factors, such as location, mining regulations, and access to infrastructure. Bauxite is typically found in tropical and subtropical regions, and the quality of the ore varies depending on the mine's location. An ideal bauxite mine is one that has abundant reserves of high-quality ore, easy access to transport routes, and a stable mining environment.

The value of bauxite mines for sale is not just in the ore itself but in the potential for long-term profitability. With aluminium being used in a wide variety of industries, from aerospace to packaging, investing in bauxite mining ensures that you are tapping into a sustainable and profitable resource that is crucial for modern economies.

Types of Bauxite Ore

Types of bauxite ore play a significant role in the extraction process and the quality of aluminium produced. Bauxite is composed primarily of aluminium oxide minerals, including gibbsite, boehmite, and diaspore, and the type of bauxite ore can vary based on the predominant mineral content.

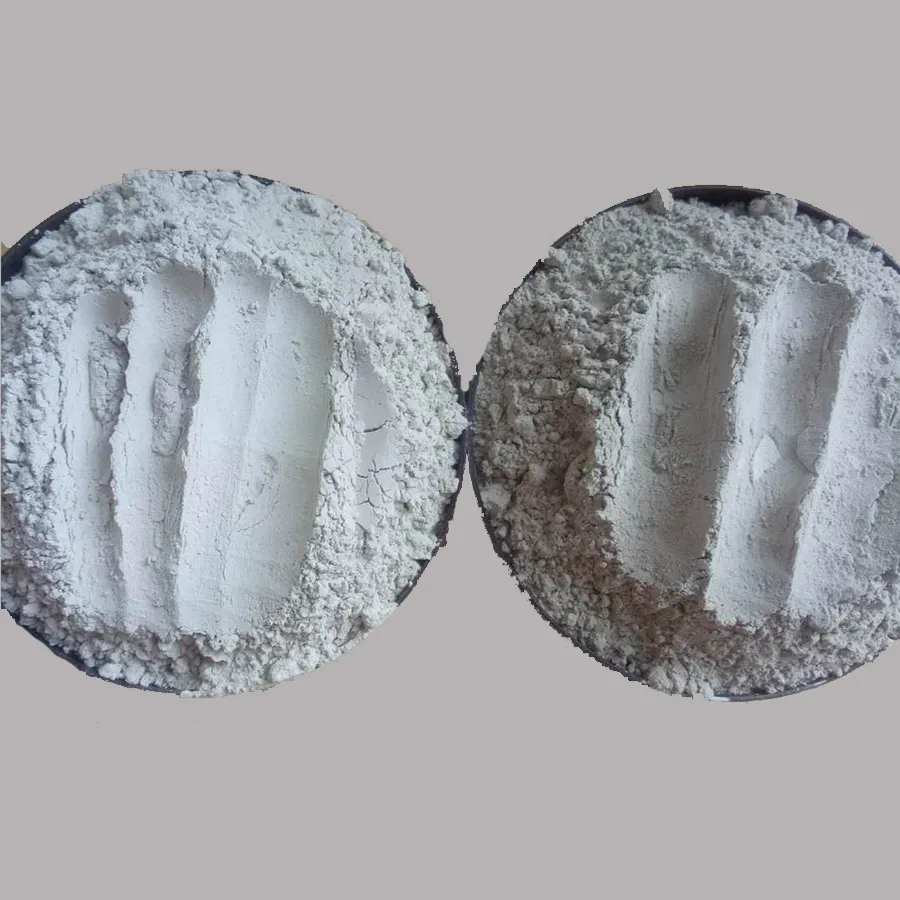

The three main types of bauxite ore are high-grade, medium-grade, and low-grade bauxite. High-grade bauxite typically contains more than 50% alumina content, making it the most efficient and cost-effective for aluminium extraction. Medium-grade and low-grade bauxites, on the other hand, have lower alumina content and may require additional processing or more complex methods to extract alumina.

Understanding the types of bauxite ore is essential for determining the best extraction method. High-grade bauxite is ideal for the Bayer process, the most commonly used method for extracting alumina from bauxite. In contrast, lower-grade bauxites may require additional refining steps or alternative methods to increase the alumina yield. The quality of the bauxite ore also impacts the overall cost-effectiveness and environmental impact of the aluminium production process.

Bauxite to Alumina to Aluminium

The process of transforming bauxite to alumina to aluminium is a crucial and complex journey. Bauxite is the primary ore from which aluminium is extracted, but before aluminium can be produced, it must first be converted into alumina (aluminium oxide) through the Bayer process.

The bauxite to alumina to aluminium process begins with the mining and crushing of bauxite ore. The crushed bauxite is then mixed with a hot, concentrated solution of sodium hydroxide, which dissolves the alumina. The resulting solution is cooled, and the alumina is separated from the impurities, forming a white powder known as alumina.

The next step in the bauxite to alumina to aluminium process is the refining of alumina into aluminium metal. This is typically achieved through the Hall-Héroult process, an electrolytic reduction method. The alumina is dissolved in molten cryolite and subjected to an electrical current, which separates the aluminium metal from the oxygen, resulting in pure aluminium.

The bauxite to alumina to aluminium journey is a highly energy-intensive process, but it is also a necessary one to produce the lightweight, durable metal that is integral to modern society. The efficient conversion of bauxite into alumina and then into aluminium is vital for maintaining a stable and cost-effective supply of aluminium for industries worldwide.

Aluminium from Bauxite

Producing aluminium from bauxite is a multi-step process that begins with the extraction of bauxite ore from the earth's crust. Once bauxite is mined, the first step in producing aluminium from bauxite is to refine the ore into alumina. This is done through the Bayer process, where the bauxite is treated with a sodium hydroxide solution to separate the alumina from the other minerals present in the ore.

Once the alumina is extracted, it undergoes further refinement in a process known as the Hall-Héroult process, where it is dissolved in molten cryolite and subjected to an electric current. This process causes the alumina to break down into aluminium metal and oxygen. The aluminium is then collected and solidified into ingots or other forms, ready for use in a variety of applications.

The production of aluminium from bauxite is a critical process for industries such as aerospace, construction, automotive, and packaging. Aluminium's lightweight and durable properties make it an essential material for creating everything from airplanes to beverage cans. As demand for aluminium continues to grow, the importance of efficient and sustainable methods for producing aluminium from bauxite becomes even more critical.

Extracting Aluminium from Bauxite

Extracting aluminium from bauxite involves a two-step process that begins with refining bauxite into alumina and then converting alumina into aluminium. The first step, the Bayer process, uses sodium hydroxide to separate alumina from the impurities in the bauxite ore. The resulting alumina is a white powder that is then subjected to the Hall-Héroult process for further refinement.

The extracting aluminium from bauxite process is energy-intensive, requiring large amounts of electricity to separate aluminium from the alumina. The Hall-Héroult process involves passing a direct current through the alumina dissolved in molten cryolite, which causes the aluminium ions to migrate to the cathode, where they are collected as aluminium metal. The oxygen produced in this process is released at the anode.

One of the key challenges in extracting aluminium from bauxite is ensuring energy efficiency and minimizing environmental impact. Efforts are underway to reduce the energy consumption and carbon emissions associated with aluminium production. Technological advancements, such as the development of more efficient electrolytic cells and alternative processing methods, are helping to make the process of extracting aluminium from bauxite more sustainable and cost-effective.

Extracting Aluminium From Bauxite FAQs

What is the first step in extracting aluminium from bauxite?

The first step is refining bauxite into alumina through the Bayer process. This involves mixing the bauxite with a hot sodium hydroxide solution to separate alumina from impurities.

How is alumina converted into aluminium?

Alumina is converted into aluminium using the Hall-Héroult process, which involves dissolving alumina in molten cryolite and applying an electrical current to separate the aluminium from oxygen.

What are the different types of bauxite ore?

The three main types of bauxite ore are high-grade, medium-grade, and low-grade. High-grade bauxite is preferred for aluminium extraction due to its higher alumina content.

What industries rely on aluminium from bauxite?

Industries such as aerospace, automotive, packaging, and construction rely heavily on aluminium produced from bauxite for its lightweight, strength, and corrosion-resistant properties.

Are there any environmental concerns with extracting aluminium from bauxite?

Yes, the process of extracting aluminium from bauxite is energy-intensive and can result in environmental concerns, such as high carbon emissions. Efforts are being made to improve energy efficiency and reduce the environmental impact of aluminium production.

Nouvelles connexes