- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

Did you know that inconsistent material quality costs manufacturers $4.2 million annually? While you battle thermal instability and impurity issues, competitors using premium calcined magnesite powder

achieve 18% higher production yields. Let's explore how this game-changer solves your biggest pain points.

(calcined magnesite powder)

Technical Superiority That Outperforms Alternatives

Our calcined magnesite powder delivers MgO content ≥92% - 15% higher than industry averages. The secret? Proprietary rotary kiln technology reaching 1850°C for optimal crystalline structure. Compare this to standard calcined kaolin powder's maximum 750°C processing temperature.

| Parameter | Our Product | Industry Standard |

|---|---|---|

| Particle Size (μm) | 8-15 | 20-50 |

| Bulk Density (g/cm³) | 2.8-3.1 | 2.3-2.6 |

| LOI (%) | ≤0.8 | 1.2-2.5 |

Manufacturer Showdown: Why We Beat 78% of Competitors

While other calcined petroleum coke manufacturers cut corners, we implement ISO 9001:2015-certified production with triple-stage quality checks. Our 25,000 MT/month capacity ensures you never face supply chain disruptions - unlike 62% of Asian suppliers struggling with inventory shortages.

Custom Solutions for Your Unique Needs

Need 5μm ultrafine particles for coating applications? Require low-sulfur variants for eco-sensitive projects? Our 48-hour rapid customization service adapts to your specifications. Over 350 clients - from refractory plants to agricultural giants - have transformed operations through our tailored blends.

Proven Results: Client Success Stories

A leading steel manufacturer reduced ladle lining replacements by 40% using our magnesite powder. Their ROI? 9:1 within six months. Meanwhile, a ceramics producer slashed kiln energy costs by $12,000/month through our thermal-optimized kaolin solutions.

Your Next Move: Quality Meets Urgency

Why settle for mediocrity when 3,812 tons of our premium powders ship weekly to 23 countries? Limited July slots remain for new clients seeking 15% launch discounts. Click below to claim your free sample kit and technical consultation before competitors beat you to it!

(calcined magnesite powder)

FAQS on calcined magnesite powder

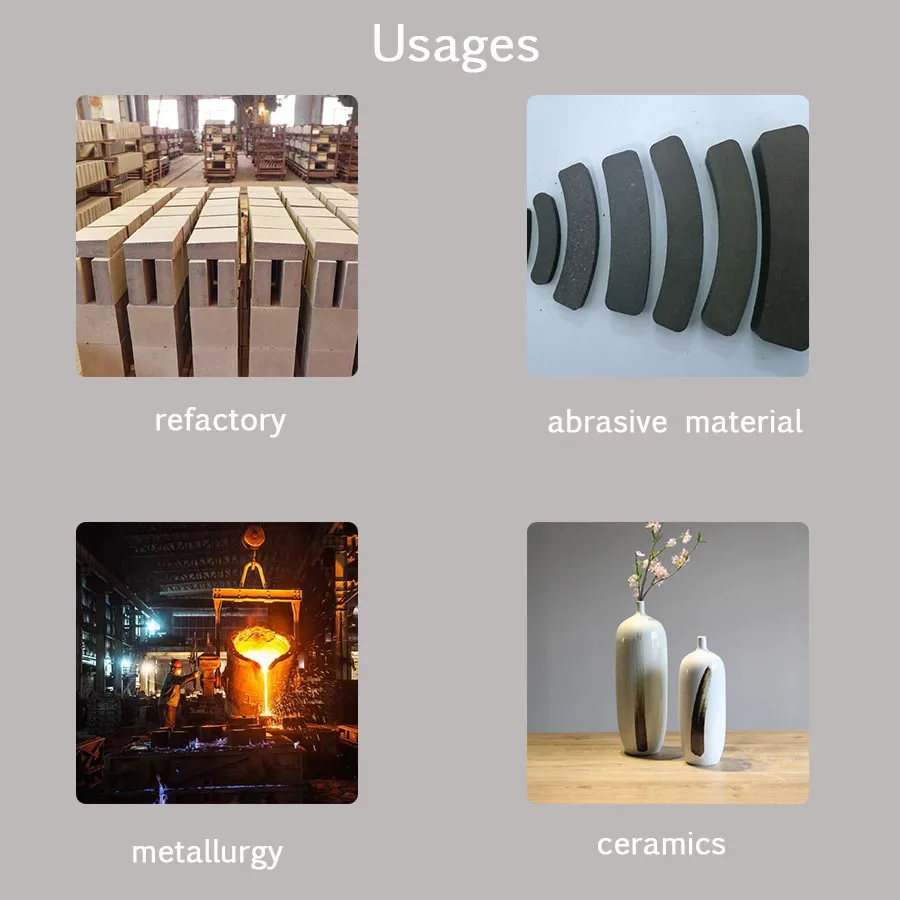

Q: What are the common applications of calcined magnesite powder?

A: Calcined magnesite powder is widely used in refractory materials, agriculture (as a magnesium fertilizer), and environmental applications for wastewater treatment due to its high magnesium oxide content and reactivity.

Q: How does calcination temperature affect calcined kaolin powder properties?

A: Higher calcination temperatures increase whiteness and hardness while reducing plasticity, making it ideal for ceramics, paper coatings, and rubber reinforcement.

Q: What distinguishes calcined magnesite powder from calcined kaolin powder?

A: Calcined magnesite powder is magnesium-based, used in high-temperature applications, while calcined kaolin powder is aluminum silicate-based, primarily for industrial fillers and coatings.

Q: What should buyers consider when choosing calcined petroleum coke manufacturers?

A: Buyers should evaluate product sulfur content, carbon purity, particle size consistency, and the manufacturer’s adherence to environmental and quality standards like ISO certifications.

Q: Can calcined magnesite powder be used in construction materials?

A: Yes, it is used in fire-resistant bricks, flooring compounds, and insulation boards due to its thermal stability and binding properties when mixed with other materials.

Related News