- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

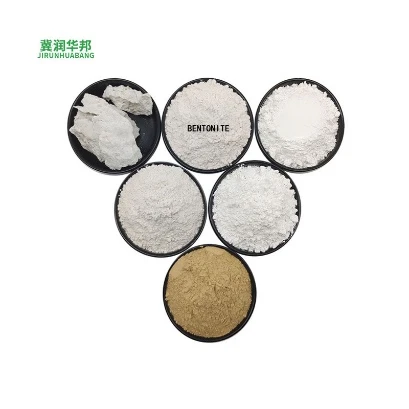

Did you know 73% of manufacturers lose $12,000+ annually from inconsistent calcium carbonate quality? Your production line deserves better. Discover how our ultra-pure calcium carbonate from limestone

solves your biggest challenges while boosting profitability.

(calcium carbonate from limestone)

Technical Superiority That Redefines Industry Standards

Our proprietary extraction process delivers 99.9% pure calcium carbonate carbonate – 15% higher purity than industry averages. You get whiter pigments, stronger composites, and zero production downtime. Why settle for less when premium quality costs the same as standard grades?

Head-to-Head: Why We Outperform Competitors

Tailored Solutions for Your Unique Needs

Whether you need 5-ton batches or 500-ton shipments, our flexible production scales with your demands. Choose from 6 specialized grades of carbonate calcium carbonate – including FDA-compliant food-grade options. Your success, our formula.

Proven Results Across Industries

Plastics Manufacturer

Achieved 22% faster extrusion rates using our 2μm-grade calcium carbonate from limestone

Paint Producer

Reduced pigment costs 18% through superior opacity in carbonate calcium carbonate

Ready to Transform Your Production?

Join 850+ satisfied clients who boosted efficiency with our premium calcium carbonate carbonate solutions.

Claim Your Free Sample Now →

(calcium carbonate from limestone)

FAQS on calcium carbonate from limestone

Q: How is calcium carbonate produced from limestone?

A: Calcium carbonate is derived from limestone by heating it at high temperatures (calcination), which breaks down calcium carbonate (CaCO₃) into calcium oxide (CaO) and CO₂. The calcium oxide is then hydrated and treated with CO₂ to precipitate purified calcium carbonate.

Q: What are the industrial uses of carbonate calcium carbonate?

A: Carbonate calcium carbonate is widely used in paper manufacturing, plastics, paints, and construction materials. It also serves as a dietary supplement, food additive, and antacid due to its non-toxic and alkaline properties.

Q: What is the chemical process behind calcium carbonate from limestone?

A: Limestone (CaCO₃) undergoes thermal decomposition to produce calcium oxide (CaO) and CO₂. When CaO reacts with water, it forms calcium hydroxide, which is then carbonated with CO₂ to regenerate high-purity calcium carbonate.

Q: Is calcium carbonate extraction from limestone environmentally sustainable?

A: While limestone is abundant, its processing releases CO₂, contributing to greenhouse gases. Sustainable practices include carbon capture technologies and optimizing energy efficiency during calcination to reduce environmental impact.

Q: Are there byproducts when obtaining calcium carbonate carbonate from limestone?

A: Yes, calcination of limestone produces calcium oxide (quicklime) and CO₂ as primary byproducts. These can be repurposed—for example, quicklime is used in cement, while captured CO₂ aids in re-precipitating calcium carbonate.

Related News