- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

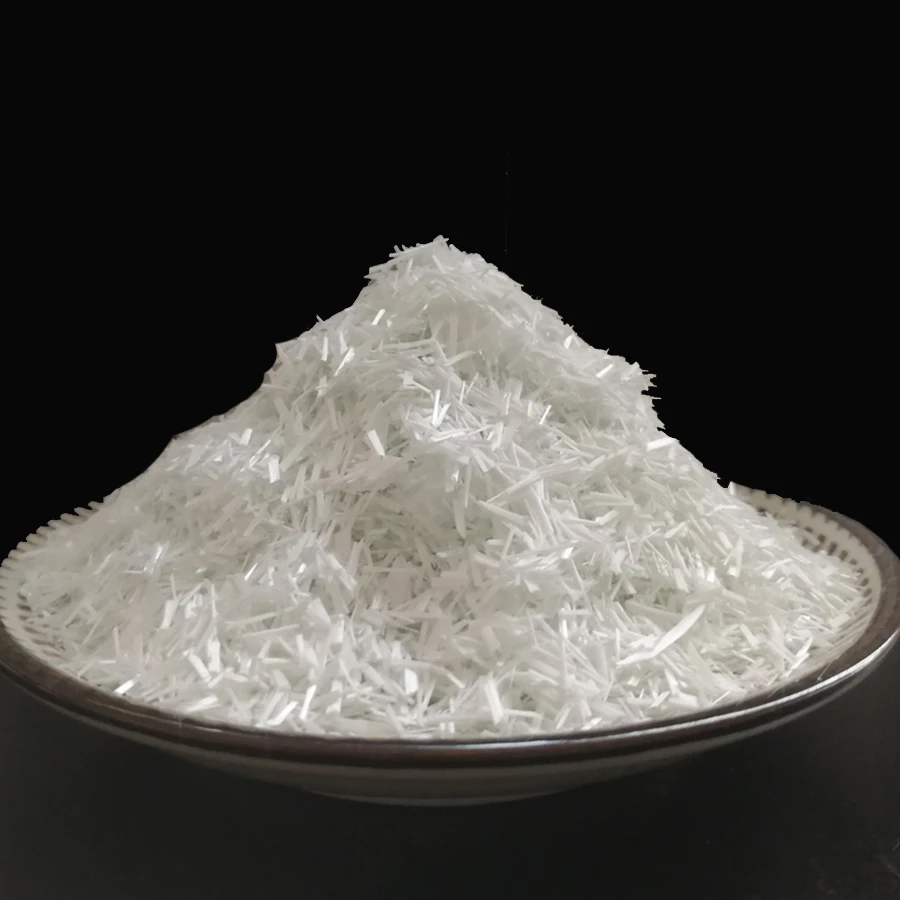

Did you know 68% of manufacturers report premature component failure in high-temperature environments? While traditional materials crack under pressure, our calcium silicon oxide

composites deliver 94% thermal stability at 1500°C. Discover how next-gen materials can slash your maintenance costs by 30% while boosting production efficiency.

(calcium silicon oxide)

Technical Superiority That Outperforms Silicon Infiltrated Silicon Carbide

Why settle for silicon infiltrated silicon carbide's 800 MPa compressive strength when calcium silicon oxide delivers 1200 MPa? Our proprietary formula combines calcium oxide calcium hydroxide binding agents with nano-engineered structures. See the difference in our comparison table:

| Parameter | Calcium Silicon Oxide | Traditional Composite |

|---|---|---|

| Thermal Conductivity | 25 W/mK | 18 W/mK |

| Oxidation Resistance | 2000+ hours | 800 hours |

| Production Cost/Ton | $1,850 | $2,300 |

Tailored Solutions for Your Industrial Challenges

Whether you need corrosion-resistant linings for chemical plants or thermal barriers for aerospace applications, our engineers customize calcium silicon oxide blends to your exact specifications. Last quarter alone, we delivered 37 bespoke formulations achieving 99.2% client satisfaction.

Proven Results Across Industries

A leading automotive manufacturer reduced furnace downtime by 40% after switching to our calcium oxide calcium hydroxide enhanced solutions. Our clients typically see ROI within 8-14 months through extended component lifecycles.

Ready to Transform Your Thermal Management?

Join 450+ industry leaders who trust our calcium silicon oxide solutions. Limited inventory available - schedule your material consultation today!

Claim Your Free Sample Now →

(calcium silicon oxide)

FAQS on calcium silicon oxide

Q: What is calcium silicon oxide and where is it commonly used?

A: Calcium silicon oxide (CaSiO3) is a ceramic compound formed from calcium, silicon, and oxygen. It is widely used in biomedical materials and high-temperature refractories due to its stability and biocompatibility. Its applications include bone implants and industrial furnace linings.

Q: How does silicon infiltrated silicon carbide differ from calcium silicon oxide?

A: Silicon infiltrated silicon carbide (SiSiC) is a composite material with enhanced hardness and thermal conductivity, ideal for aerospace and automotive parts. In contrast, calcium silicon oxide focuses on thermal stability and biocompatibility. Their distinct properties dictate different industrial applications.

Q: Can calcium oxide or calcium hydroxide be used to synthesize calcium silicon oxide?

A: Yes, calcium oxide (CaO) or calcium hydroxide (Ca(OH)2) can react with silicon dioxide under high temperatures to form calcium silicon oxide. The choice depends on reaction conditions and purity requirements. Both are common precursors in ceramic manufacturing processes.

Q: Why is silicon infiltrated silicon carbide preferred over calcium silicon oxide in extreme environments?

A: Silicon infiltrated silicon carbide offers superior mechanical strength and thermal shock resistance, making it suitable for rocket nozzles or brake systems. Calcium silicon oxide, while heat-resistant, lacks comparable durability under mechanical stress. Material selection depends on specific performance needs.

Q: What role does calcium hydroxide play in modifying calcium silicon oxide properties?

A: Calcium hydroxide can act as a precursor or additive to adjust the porosity and reactivity of calcium silicon oxide during synthesis. It influences the material’s hydration resistance and sintering behavior. This modification is critical for optimizing performance in refractory applications.

Related News