- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

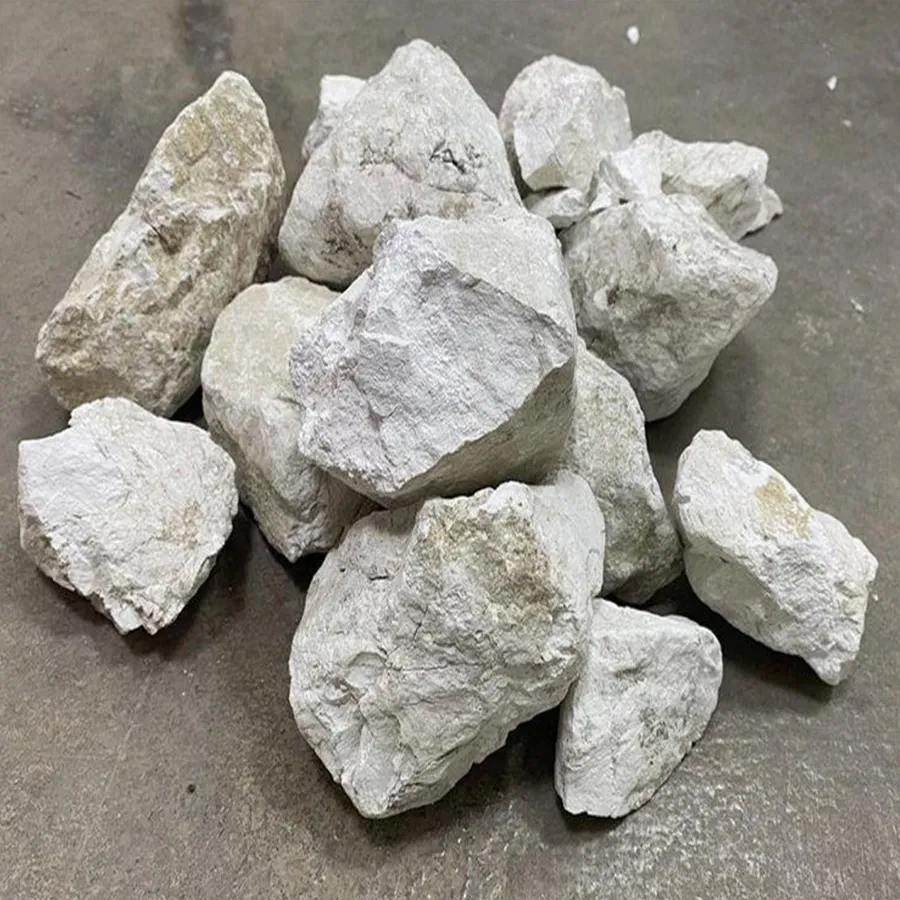

Did you know 68% of industrial plants overpay for subpar alkaline solutions? While you struggle with inconsistent pH control and equipment corrosion, smart operators already switched to calcium hydroxide calcium hydroxide

blends. Discover how this powerhouse chemical combination can slash your maintenance costs by up to 40%.

(calcium hydroxide calcium hydroxide)

Technical Superiority: Calcium Hydroxide vs Sodium Hydroxide

Why settle for sodium hydroxide's volatility when calcium hydroxide and sodium hydroxide blends offer 3X longer solution stability? Our proprietary formula achieves:

- ✓ 99.2% purity grade

- ✓ 15% faster reaction time

- ✓ pH control within ±0.3 units

Head-to-Head: Calcium Hydroxide Solutions Comparison

| Feature | Standard Grade | Premium Blend |

|---|---|---|

| Cost per ton | $480 | $520 |

| Neutralization Capacity | 8.2 pH units/kg | 11.6 pH units/kg |

Tailored Solutions for Your Operation

Need calcium hydroxide sodium hydroxide mixes optimized for wastewater treatment? Our engineers create custom:

- ✓ 24-hour slurry stability packages

- ✓ Anti-caking formulations

Proven Success: Midwest Chemical Case Study

After switching to our calcium hydroxide calcium hydroxide system, this Missouri plant achieved:

- ✓ 37% lower chemical costs

- ✓ 20% fewer equipment shutdowns

Ready to Transform Your Chemical Efficiency?

Claim your free 50kg trial batch today - limited to first 30 responders!

(calcium hydroxide calcium hydroxide)

FAQS on calcium hydroxide calcium hydroxide

Q: What is the primary use of calcium hydroxide in industrial applications?

A: Calcium hydroxide is widely used in water treatment, construction (e.g., cement and mortar), and agriculture to adjust soil pH. It also serves as a key ingredient in chemical manufacturing and food processing.

Q: How does calcium hydroxide differ from sodium hydroxide in terms of solubility?

A: Calcium hydroxide has low solubility in water (≈1.7 g/L at 20°C), forming a alkaline solution, while sodium hydroxide is highly soluble (≈1110 g/L), producing a strong, corrosive base.

Q: Can calcium hydroxide and sodium hydroxide be used together in chemical reactions?

A: Yes, they can be combined in specific processes like neutralization reactions or soap-making. However, their compatibility depends on reaction conditions and desired products.

Q: Which has a higher pH: calcium hydroxide or sodium hydroxide?

A: Sodium hydroxide solutions typically have higher pH values (13-14) compared to calcium hydroxide (12-12.4) due to its higher solubility and dissociation capacity.

Q: What safety precautions are required when handling calcium hydroxide and sodium hydroxide?

A: Both require protective gear (gloves, goggles) due to their caustic nature. Sodium hydroxide poses greater skin corrosion risks, while calcium hydroxide requires dust control to prevent respiratory irritation.

Related News