- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

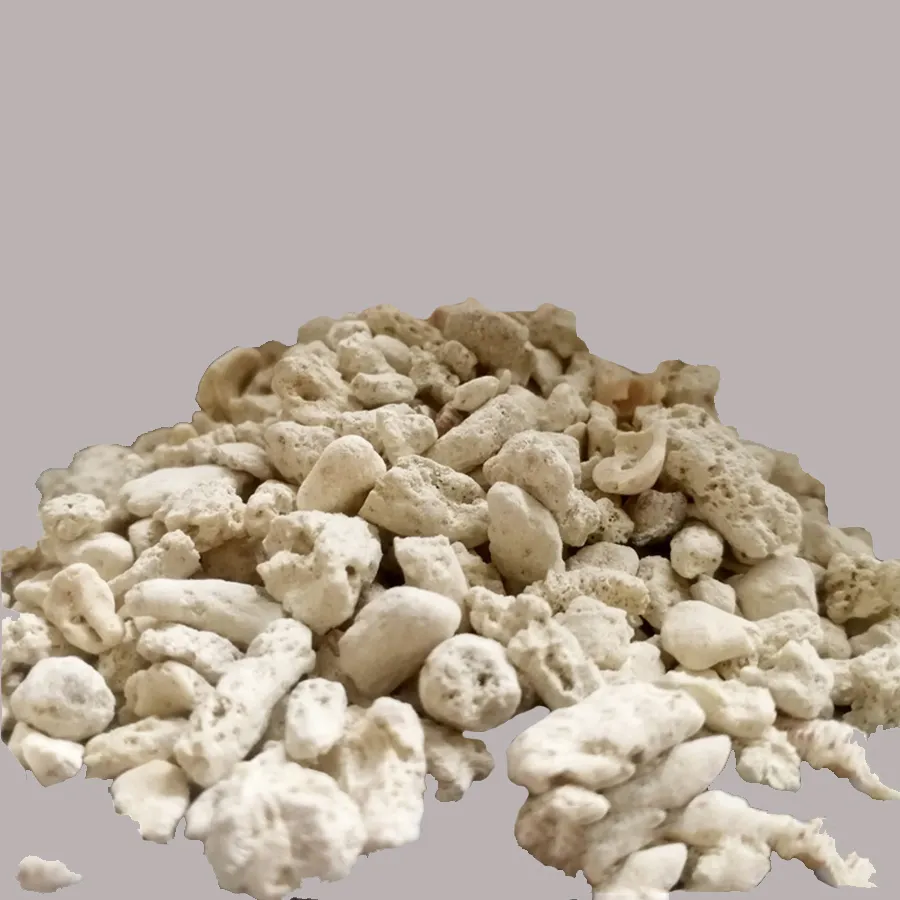

In the vast landscape of industrial minerals, a material stands out for its exceptional versatility and performance: Coral Sand. Far from a mere aggregate, this specialized product, meticulously processed and rigorously tested, is emerging as a critical component across a myriad of applications, from advanced water purification systems to high-performance construction materials. Its unique mineralogical composition and precise granular structure offer unparalleled advantages in efficiency, durability, and environmental sustainability. At Baifeng Mining, we are committed to delivering premium Coral Sand that meets the stringent demands of modern industry, leveraging cutting-edge technology and decades of expertise.

Industry Trends and the Growing Demand for Coral Sand

The global industrial minerals market is experiencing a significant shift, driven by increasing regulatory pressures for environmental protection, a heightened focus on resource efficiency, and the rapid expansion of infrastructure and manufacturing sectors. Within this dynamic environment, the demand for high-purity, specialized minerals like Coral Sand is accelerating. Key trends include:

- Sustainable Filtration Solutions: With growing concerns over water scarcity and pollution, industries are seeking more effective and eco-friendly filtration media. Coral Sand, with its natural purity and excellent filtration properties, is becoming a preferred choice over synthetic alternatives.

- Advanced Material Science: The development of specialized concretes, composites, and geotechnical solutions demands aggregates with precise physical and chemical properties. Coral Sand provides the necessary consistency and performance.

- Resource Optimization in Metallurgy: As industries strive for greater energy efficiency and reduced waste, the use of high-quality fluxing agents and foundry sands, which includes specific grades of Coral Sand, becomes paramount for improved process control and product quality.

According to a 2023 market analysis by Grand View Research, the global industrial minerals market size was valued at USD 350 billion in 2022 and is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% from 2023 to 2030, driven largely by sectors that extensively utilize specialized sands. This trajectory underscores the increasing strategic importance of materials like Coral Sand in fostering industrial growth and sustainability.

Understanding Coral Sand: Technical Parameters and Properties

Coral Sand is a highly refined industrial mineral characterized by its exceptional purity and consistent granular structure. It is primarily composed of high-grade silica (SiO2), making it chemically inert and highly durable. The term "Coral Sand" often denotes its specific geological origin or refined appearance, setting it apart from common construction sands.

Below is a table detailing key technical specifications that define the quality and performance of premium Coral Sand:

| Parameter | Typical Value Range | Significance |

|---|---|---|

| SiO2 Content (Purity) | ≥ 98.5% | Indicates high chemical inertness, crucial for sensitive applications like water filtration and specialty glass. High purity minimizes contaminants. |

| Mohs Hardness | 6.5 - 7.0 | Reflects resistance to scratching and abrasion, ensuring long lifespan in abrasive environments and stable particle size over time. |

| Specific Gravity | 2.65 - 2.75 g/cm³ | Important for calculating bulk density and hydraulic characteristics in filtration beds; ensures stable media layers. |

| Bulk Density (Loose) | 1.45 - 1.60 g/cm³ | Used for transportation and storage calculations, influences the volume required for a given weight. |

| Acid Solubility | ≤ 0.5% | Measures resistance to acidic environments, critical for applications in chemical processing, wastewater treatment, and boiler feed water. |

| Moisture Content | ≤ 0.1% | Indicates effective drying processes, prevents clumping, and ensures consistent flow and weight accuracy during handling. |

| Uniformity Coefficient (UC) | A measure of particle size distribution uniformity. A lower UC indicates a more uniform material, vital for efficient filtration and predictable flow rates. | |

| Effective Size (ES) | 0.45 - 0.55 mm (adjustable by grade) | The sieve opening through which 10% of the sand by weight will pass. Crucial for designing filtration systems to achieve desired filtrate quality. |

| Roundness/Sphericity | Sub-angular to Rounded | Influences porosity, permeability, and backwash characteristics in filtration media. Rounded grains typically offer better flow and less clogging. |

| Turbidity | Indicates cleanliness and absence of fine particulate matter, critical for water treatment applications to prevent initial filtrate contamination. |

These parameters are rigorously tested in accordance with international standards such as ISO 9001 for quality management and specific ASTM standards (e.g., ASTM C778 for Standard Sand) for material properties, ensuring that every batch of Coral Sand from Baifeng Mining meets the highest industry benchmarks.

The Meticulous Manufacturing Process of Coral Sand

Producing high-grade Coral Sand is a complex, multi-stage process that goes beyond simple extraction. It involves precision engineering and stringent quality control at every step to ensure the product meets specific industrial requirements. Our process emphasizes material purity, consistent particle size distribution, and optimal physical properties. While it doesn't involve traditional casting or forging, the process is a sophisticated form of beneficiation and refinement.

Process Flow Explained:

-

Raw Material Sourcing & Pre-screening:

We begin by carefully selecting high-quality silica deposits known for their purity and mineral consistency. Initial excavation is followed by coarse screening to remove oversized materials and preliminary impurities.

Raw Material Extraction → Primary Screening

-

Crushing & Grinding:

The screened raw material undergoes multi-stage crushing, typically using jaw crushers and cone crushers, to reduce it to a manageable size. This is followed by grinding in ball mills or rod mills to achieve the desired granular range, optimizing for both particle shape and size uniformity.

Primary Screening → Crushing → Grinding

-

Washing & Purification:

This is a critical step for achieving high purity. The material is subjected to intensive washing using high-pressure water jets and attrition scrubbing. This process effectively removes clay, organic matter, and other soluble or fine impurities adhering to the sand grains. Specialized hydrocyclones and spiral classifiers are often employed to further separate lighter impurities from the heavier silica particles.

Grinding → Multi-stage Washing & Attrition Scrubbing → Hydrocyclone/Spiral Classification

-

Drying:

After washing, the wet sand is fed into large rotary dryers or fluid bed dryers. This stage is crucial for reducing moisture content to below 0.1%, preventing clumping and ensuring a free-flowing product, which is essential for consistent processing and application.

Hydrocyclone/Spiral Classification → Drying

-

Sieving & Grading (Screening):

The dried Coral Sand is then precisely sorted using multi-deck vibratory screens into various grades based on particle size (e.g., different mesh sizes). This step ensures a very narrow and consistent particle size distribution for each product variant, meeting specific customer requirements for effective size and uniformity coefficient.

Drying → Multi-deck Precision Sieving & Grading

-

Quality Control & Packaging:

Throughout the entire process, rigorous quality control checks are performed. Samples are regularly taken and analyzed in our state-of-the-art laboratory for chemical composition (e.g., SiO2, Fe2O3 content), physical properties (e.g., specific gravity, bulk density, effective size, uniformity coefficient, acid solubility), and purity. Only material that passes all tests, adhering to ISO and ASTM standards, proceeds to final packaging (bulk bags, smaller sacks, or loose bulk) for shipment.

Precision Sieving → Final Quality Control (Lab Analysis) → Packaging

The material used is high-purity natural silica. The manufacturing process is primarily mechanical and physical beneficiation, not casting or forging, which are relevant for metal components. Detection standards strictly adhere to international benchmarks like ISO 9001 (Quality Management), ASTM (American Society for Testing and Materials) standards for granular materials (e.g., ASTM C778), and specific industry standards for filtration media or proppants. The expected lifespan of Coral Sand in typical applications like filtration is decades, assuming proper backwash and maintenance, due to its inherent hardness and chemical stability.

Unrivaled Technical Advantages of Baifeng Mining's Coral Sand

Our commitment to excellence in the manufacturing process translates directly into superior product performance and significant advantages for our clients across various industries:

- Exceptional Purity and Chemical Inertness: With SiO2 content consistently above 98.5%, our Coral Sand is virtually free of deleterious impurities such as iron oxides, alumina, and organic matter. This high purity ensures chemical stability, making it ideal for use in sensitive environments where reactions with the media must be avoided, such as in ultra-pure water production or aggressive chemical filtration. Its low acid solubility (<0.5%) guarantees longevity even under harsh conditions.

- Optimized Filtration Efficiency: The precise control over particle size distribution and uniformity coefficient (UC < 1.5) provides excellent porosity and permeability in filtration beds. This results in superior turbidity removal, longer filter run times, and reduced backwash frequency, directly translating to energy savings (less pumping for backwash) and lower operational costs for water treatment plants.

- Superior Durability and Longevity: With a Mohs hardness of 6.5-7.0, Coral Sand exhibits exceptional resistance to abrasion and degradation. This robust nature significantly extends the material's service life, reducing the need for frequent media replacement and associated downtime, thereby contributing to lower maintenance costs and continuous operation.

- High Thermal Stability: Coral Sand can withstand high temperatures without significant changes in its physical or chemical properties, making it suitable for applications in high-temperature environments like foundries or specialized refractory mixes.

- Eco-Friendly and Sustainable: As a naturally derived mineral, Coral Sand is an environmentally sound choice. Its long service life further reduces environmental impact by minimizing waste generation and transportation needs associated with media replacement.

Diverse Application Scenarios

The unique properties of Coral Sand make it indispensable across a broad spectrum of industrial applications:

-

Water Treatment & Purification (Municipal & Industrial):

As a primary filtration media, Coral Sand is widely used in rapid gravity filters and pressure filters to remove suspended solids, turbidity, and colloidal matter from drinking water, wastewater, and industrial process water (e.g., boiler feed water, cooling tower water). Its consistent particle size ensures efficient pollutant capture while allowing for effective backwashing, reducing filter bed fouling. This contributes to significant energy savings by maintaining optimal hydraulic flow and reducing pump loads.

-

Oil & Gas Industry (Proppant & Filtration):

In hydraulic fracturing, specialized grades of Coral Sand act as proppants, holding open induced fractures to facilitate oil and gas flow. Its high crush strength and roundness are critical for maintaining permeability under immense subterranean pressures. It's also utilized in drilling fluid filtration to protect valuable downhole equipment.

-

Metallurgy & Foundry Industry:

High-purity Coral Sand serves as a critical component in foundry molds and cores due to its high refractoriness, low thermal expansion, and excellent permeability, ensuring defect-free castings. It's also used as a fluxing agent in metallurgical processes to lower melting points and remove impurities.

-

Construction & Infrastructure:

Used as a high-performance aggregate in specialty concretes, mortars, and grouts where high strength, durability, and specific aesthetic qualities are required. Its consistent grading contributes to predictable mix designs and superior finished products. In some niche applications, it can enhance resistance to certain forms of corrosion.

-

Glass Manufacturing:

High-purity Coral Sand is a primary raw material for producing various types of glass, including flat glass, container111 glass, and specialty glass, due to its low iron content and consistent SiO2 levels, which directly impact glass clarity and strength.

-

Chemical Industry:

Acts as an inert filler or a raw material in the production of silicon chemicals, silicates, and other compounds where high purity silica is essential.

Choosing the Right Partner: Manufacturer Comparison

Selecting a supplier for industrial minerals like Coral Sand is a strategic decision that impacts operational efficiency, product quality, and long-term cost. While many suppliers exist, Baifeng Mining distinguishes itself through a commitment to excellence across several critical areas:

| Criterion | Typical Manufacturer | Baifeng Mining Advantage |

|---|---|---|

| Product Purity & Consistency | Varies widely; inconsistent batches; may contain higher impurities. | Guaranteed >98.5% SiO2; uniform particle size (UC < 1.5) due to multi-stage processing and rigorous lab testing (ISO, ASTM standards). |

| Manufacturing Process | Basic crushing, washing, and screening; limited control over particle shape/distribution. | Advanced beneficiation, attrition scrubbing, multi-deck precision sieving, ensuring optimal shape and narrow distribution for specific applications. |

| Quality Control & Certifications | Minimal or self-regulated QC; few external certifications. | Full in-house laboratory testing for every batch; adherence to ISO 9001 and relevant ASTM standards; full material traceability. |

| Customization Capabilities | Limited to standard grades. | Extensive R&D and production flexibility to tailor particle size, purity levels, and specific treatments to unique client specifications. |

| Technical Support & Expertise | Basic product information; limited post-sales support. | Dedicated team of mineralogy experts and application engineers; provide consultation, design recommendations, and troubleshooting support. |

| Supply Chain Reliability | Potential for delays, inconsistent delivery. | Robust logistics network, strategic inventory management, and proven track record of on-time global deliveries. |

| Environmental Responsibility | May not prioritize sustainable practices. | Commitment to responsible mining, water recycling in processing, and minimal environmental footprint. |

Choosing Baifeng Mining means partnering with a company that prioritizes quality, precision, and client success, ensuring you receive not just Coral Sand, but a tailored solution that enhances your operational efficiency and product quality.

Tailored Solutions: Customization for Your Needs

Recognizing that no two industrial applications are exactly alike, Baifeng Mining offers comprehensive customization services for our Coral Sand products. Our expert team works closely with clients to understand their specific requirements and design a Coral Sand solution that perfectly aligns with their operational parameters and desired outcomes.

- Granulometry (Particle Size Distribution): We can precisely adjust the effective size (ES) and uniformity coefficient (UC) to meet specific filtration velocities, permeability requirements, or aggregate packing densities. Whether you need finer grades for polishing filters or coarser media for support layers, our advanced sieving capabilities allow for precise control.

- Purity Levels: While our standard Coral Sand boasts high purity, for highly sensitive applications (e.g., semiconductors, specialized chemicals), we can implement additional purification steps to achieve even lower impurity levels (e.g., extremely low iron or alumina content).

- Surface Treatment & Washing: Depending on the application, we can provide additional washing or surface treatments to remove ultra-fine particles, reduce dust, or modify surface chemistry for enhanced performance in specific binders or matrices.

- Packaging Solutions: From bulk shipments (rail, truck, sea container111) to various bag sizes (25kg, 50kg, 1-tonne bulk bags) or custom packaging with specific labeling, we ensure the product arrives in optimal condition and is easy to integrate into your existing logistics.

- Technical Consultation and R&D Support: Our team of geologists, material scientists, and application engineers is available to consult on complex projects, offer feasibility studies, and collaborate on R&D for novel applications or challenging material specifications. We can provide sample batches for testing and validation.

This bespoke approach ensures that clients receive a product optimally suited to their unique needs, maximizing performance and return on investment.

Success Stories: Real-World Application Cases

The practical benefits of Baifeng Mining's Coral Sand are best illustrated through its successful deployment in challenging industrial environments:

Case Study 1: Municipal Water Treatment Plant Upgrade

A major municipal water treatment facility in a rapidly growing metropolitan area faced increasing challenges with turbidity and seasonal algal blooms, leading to frequent backwashing and high operational costs. Their existing filter media was nearing the end of its lifespan and lacked the efficiency needed for future demands.

Solution: Baifeng Mining supplied over 5,000 tonnes of specialized Coral Sand, precisely graded for their rapid gravity filter beds (Effective Size 0.50mm, UC < 1.4). Our engineers provided technical guidance on media layering and installation.

Results: Within three months of implementation, the plant reported a 30% reduction in backwash frequency, leading to significant savings in water consumption (over 20 million liters annually) and pumping energy (estimated 15% reduction). Filtrate turbidity consistently remained below 0.1 NTU, surpassing regulatory requirements. The project demonstrated the superior filtration efficiency and long-term durability of Coral Sand.

Case Study 2: Industrial Wastewater Remediation in Petrochemical Sector

A large petrochemical complex was struggling with complex industrial wastewater containing suspended solids, oil residues, and various chemical contaminants, requiring extensive pre-treatment before discharge. Traditional filtration media showed rapid fouling and required frequent replacement due to the aggressive chemical environment.

Solution: We provided a custom blend of chemically stable Coral Sand with enhanced acid and alkali resistance, tailored for their multi-media filters. The material's low acid solubility (0.3%) and high purity were critical for performance in this corrosive environment.

Results: The new filtration system, utilizing Baifeng Mining's Coral Sand, achieved a 40% improvement in suspended solids removal and extended filter media lifespan by over 200% compared to their previous media. This reduced maintenance downtime by 25% and significantly lowered waste disposal costs associated with media replacement, demonstrating its exceptional performance in demanding environments and contributing to substantial cost savings and environmental compliance.

Ensuring Excellence: Quality Assurance & Standards

At Baifeng Mining, quality is not just a promise; it's an ingrained part of our operational philosophy. Our comprehensive Quality Assurance (QA) program ensures that every gram of Coral Sand delivered meets the highest global standards and client specifications.

- ISO 9001 Certified Processes: Our entire production chain, from raw material sourcing to final packaging and logistics, operates under a stringent ISO 9001 certified Quality Management System. This ensures consistent quality, continuous improvement, and customer satisfaction.

- State-of-the-Art Laboratory Testing: We operate a fully equipped, modern laboratory capable of conducting comprehensive chemical and physical analyses. Key tests include X-ray Fluorescence (XRF) for elemental composition, sieve analysis for particle size distribution (conforming to ASTM E11), specific gravity, bulk density, acid solubility, turbidity, and crush strength tests. Every production batch undergoes rigorous testing before release.

- Material Traceability: Each batch of Coral Sand is assigned a unique identifier, allowing for complete traceability from the mining face through processing, quality control, and delivery. This provides an unparalleled level of transparency and accountability.

-

Adherence to Industry Standards: Our products consistently meet or exceed relevant international standards, including but not limited to:

- ASTM C778: Standard Specification for Standard Sand.

- AWWA B100: American Water Works Association standards for filtering material.

- ISO 13503-2: Petroleum and natural gas industries—Completion fluids and materials—Part 2: Measurement of properties of proppants used in hydraulic fracturing and gravel-packing operations.

- Continuous Improvement: Through regular audits, performance reviews, and customer feedback mechanisms, we continually refine our processes and product offerings, staying at the forefront of mineral processing technology.

Our unwavering commitment to quality ensures that when you choose Baifeng Mining's Coral Sand, you are investing in a reliable, high-performance solution that delivers consistent results.

Trust & Support: FAQ, Delivery & Warranty

At Baifeng Mining, we believe in building long-term relationships based on trust and mutual success. Our commitment extends beyond product delivery to comprehensive customer support and transparent policies.

Frequently Asked Questions (FAQ) about Coral Sand

A1: Our Coral Sand is primarily composed of high-purity Silicon Dioxide (SiO2), typically achieving levels of 98.5% or higher, ensuring chemical inertness and durability for various industrial applications.

A2: The Effective Size (ES) dictates the hydraulic characteristics and filtration rate, while the Uniformity Coefficient (UC) indicates the range of particle sizes. A lower UC (e.g., <1.5) signifies a more uniform product, leading to better filter bed performance, reduced clogging, and more efficient backwashing, ultimately enhancing filtration efficiency and extending media lifespan.

A3: Our Coral Sand production and quality control adhere to rigorous international standards including ISO 9001 for quality management, and relevant ASTM standards such as ASTM C778 for Standard Sand specifications, and AWWA B100 for filtering materials in water treatment.

A4: Yes, due to its high silica content, Coral Sand exhibits excellent thermal stability and high refractoriness, making it ideal for applications in foundries, refractory mixes, and other high-temperature industrial processes.

A5: Given its high Mohs hardness (6.5-7.0) and chemical inertness, Coral Sand can have a service life of 10-20 years or more in well-maintained water filtration systems, significantly outperforming less durable media.

A6: Absolutely. We specialize in providing tailored solutions. We can adjust particle size distribution, purity levels, and even provide specific surface treatments to meet unique project specifications. Our R&D team is available for consultation on complex customization needs.

A7: We are committed to sustainable practices, including responsible mining techniques that minimize land disturbance, efficient water recycling in our processing plants, and strict adherence to environmental regulations. Our goal is to balance resource extraction with ecological preservation.

Delivery Cycle & Logistics

We understand that timely delivery is crucial for your operations. Baifeng Mining maintains a robust logistics network capable of supporting both domestic and international shipments. Our standard delivery lead times typically range from 7 to 21 working days, depending on order volume, customization requirements, and destination. For urgent orders, expedited shipping options are available upon request. We work with trusted carriers to ensure your Coral Sand arrives safely and on schedule, whether it's in bulk, supersacks, or smaller bags.

Quality Warranty & Customer Support

Baifeng Mining stands behind the quality of our Coral Sand with a comprehensive quality warranty. We guarantee that our products meet the specifications outlined in our technical data sheets and agreed-upon contract terms. In the unlikely event of any deviation, our dedicated customer support team is ready to address your concerns promptly and efficiently.

Our support services include:

- Pre-Sales Consultation: Expert guidance on product selection and technical specifications.

- In-Sales Support: Real-time order tracking and logistics updates.

- After-Sales Assistance: Technical troubleshooting, performance optimization advice, and warranty claims processing.

Your satisfaction is our priority. Contact us today to learn how Baifeng Mining's Coral Sand can elevate your industrial processes.

Concluding Thoughts and Industry Outlook

As industries worldwide grapple with the complexities of resource scarcity, environmental responsibility, and the ever-increasing demand for higher performance, materials like Coral Sand will play an increasingly pivotal role. Its unique combination of purity, durability, and versatility positions it as a cornerstone in sustainable industrial development. At Baifeng Mining, we are proud to be at the forefront of supplying this essential mineral, empowering our clients to achieve their operational and environmental objectives with unparalleled efficiency and reliability. The future of industrial processing will undoubtedly rely on high-quality, specialized raw materials, and Coral Sand is poised to lead that charge.

References and Further Reading

For more in-depth insights into industrial minerals and their applications, consider exploring the following resources:

- Geological Survey of America (GSA) Journals: Provides peer-reviewed articles on mineralogy and economic geology.

https://pubs.geoscienceworld.org/gsa

- American Water Works Association (AWWA): Offers publications and standards related to water treatment and infrastructure.

https://www.awwa.org/publications/journal-awwa

- Industrial Minerals Association - North America (IMA-NA): Industry insights and advocacy for industrial minerals.

https://www.ima-na.org/knowledge-center/publications

- International Organization for Standardization (ISO): Details on quality management systems and product standards.

https://www.iso.org/standards.html

- ASTM International: Provides globally recognized consensus standards for materials, products, systems, and services.

https://www.astm.org/standards

Related News