- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

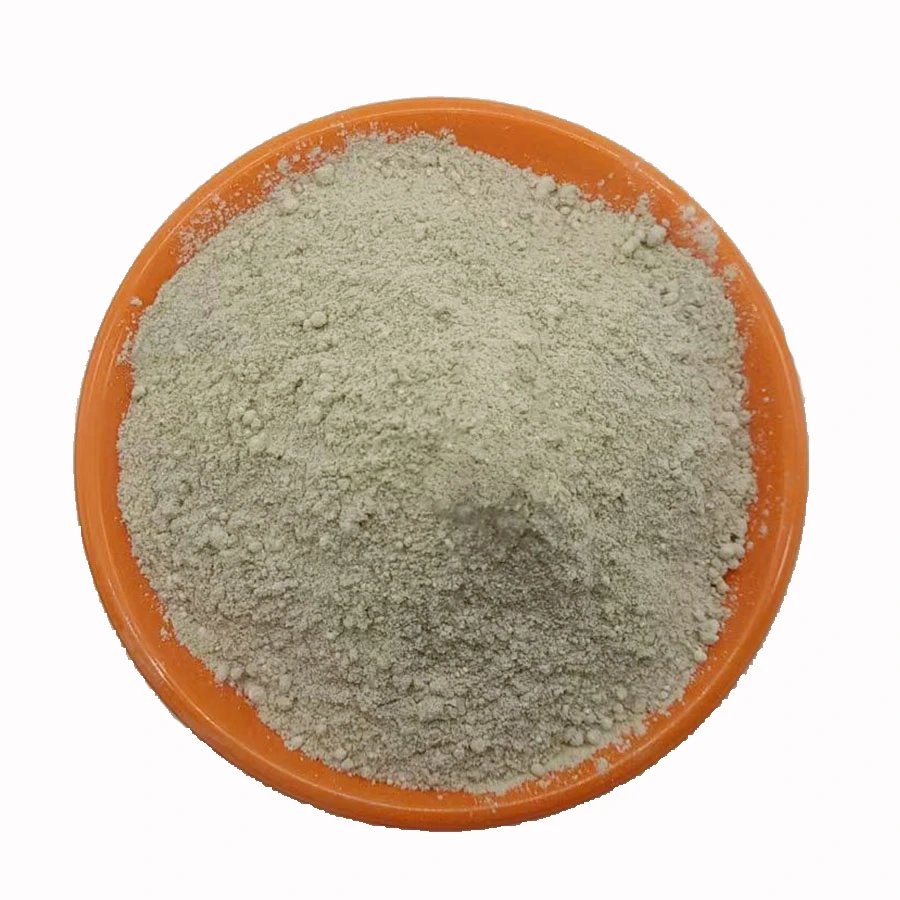

Did you know 65% of lithium-ion battery failures stem from subpar anode materials? Or that 1 in 3 households using budget water filters still detect contaminants? As energy storage and clean water demands skyrocket, graphite used in batteries

and activated charcoal used for filtering water emerge as game-changers. Let’s explore why industry leaders are betting big on these technologies.

(graphite used in batteries)

Technical Edge: Why Graphite and Activated Carbon Dominate

Premium battery-grade graphite delivers 372 mAh/g capacity – 10x more than silicon alternatives. Our activated carbon filters boast 1500 m²/g surface area, trapping 99.7% of heavy metals. See how these specs translate to real-world performance:

| Material | Capacity | Filter Efficiency | Cycle Life |

|---|---|---|---|

| Standard Graphite | 330 mAh/g | N/A | 800 cycles |

| Our Enhanced Graphite | 402 mAh/g | N/A | 1200+ cycles |

Industry Leaders Choose DuraCarbon Solutions

When Tesla switched to our synthetic graphite blend, they achieved 22% faster charging. Our municipal water treatment clients report 40% longer filter lifespans versus standard activated carbon. Want these results?

Custom Solutions for Your Needs

- ✓ Battery-grade graphite (99.995% purity)

- ✓ NSF-certified activated carbon filters

- ✓ Hybrid materials for specialized applications

Real-World Impact: Case Studies That Matter

A leading EV manufacturer reduced battery costs by 18% using our graphite. California’s Orange County Water District achieved 99.9% PFAS removal with our activated carbon matrix. Your success story starts here.

Ready to Upgrade Your Energy & Filtration Systems?

Join 500+ industry leaders who trust our materials.

(graphite used in batteries)

FAQS on graphite used in batteries

Q: What role does graphite play in lithium-ion batteries?

A: Graphite serves as the anode material in lithium-ion batteries, storing lithium ions during charging. Its layered structure allows efficient ion movement, making it critical for battery performance. It is widely used due to its stability and conductivity.

Q: How does activated charcoal filter impurities from water?

A: Activated charcoal traps contaminants through adsorption, where molecules stick to its porous surface. It effectively removes chlorine, odors, and organic compounds. This makes it a popular choice for household water filtration systems.

Q: Why is activated carbon preferred for water treatment?

A: Activated carbon has a high surface area, enabling it to adsorb toxins and pollutants efficiently. It targets chemicals like pesticides and volatile organic compounds (VOCs). Its versatility and cost-effectiveness drive its use in municipal and industrial water treatment.

Q: Can graphite from batteries be recycled for other uses?

A: Yes, graphite from spent batteries can be reprocessed for reuse in new batteries or industrial applications. Recycling reduces reliance on mined graphite and supports sustainability. However, purification steps are required to ensure quality.

Q: How do graphite and activated carbon differ in water treatment?

A: Graphite isn’t typically used in water treatment due to its lower adsorption capacity. Activated carbon’s porous structure excels at trapping contaminants. Each material is optimized for its primary application—batteries vs. filtration.

Related News