- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

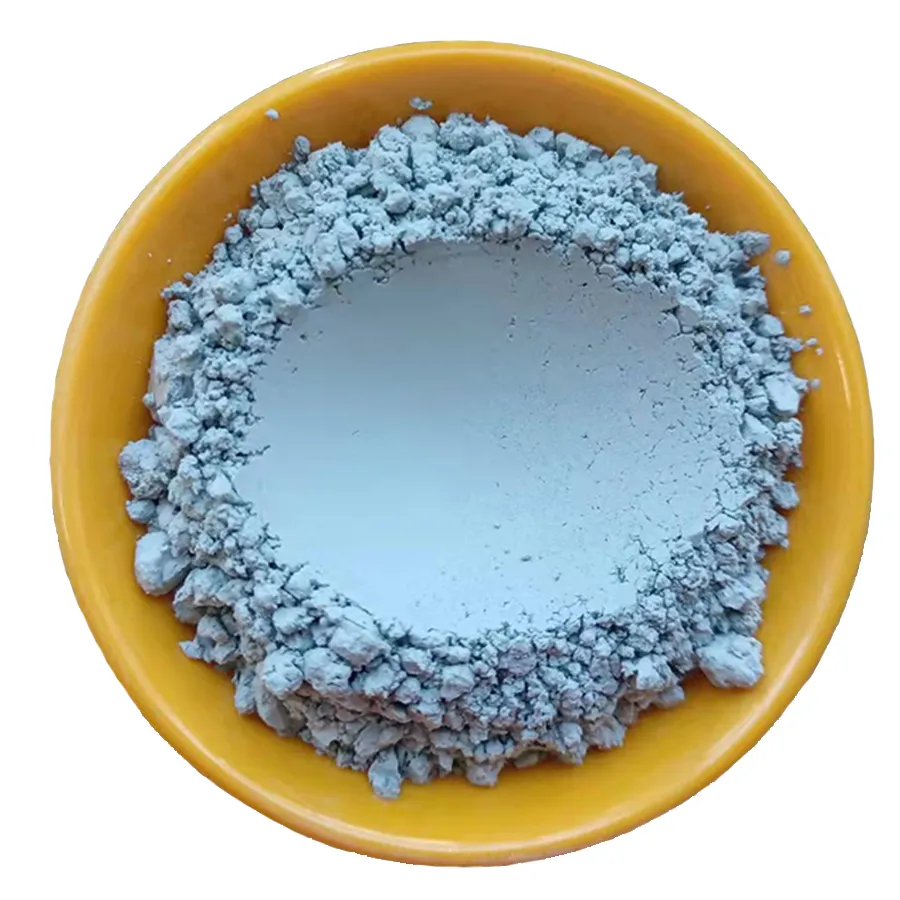

Conductive Mica Powder is a finely processed mineral functional filler made from natural mica or synthetic phlogopite, modified with conductive elements. It offers outstanding electrical conductivity, thermal stability, anti-static performance, and corrosion resistance, making it a key component in smart coatings, EMI/RFI shielding, automotive, electronics, petrochemical, and other high-tech industries.

According to MarketsandMarkets 2023 Report, the global functional mica market (including conductive grades) has grown at a CAGR of 5.3% from 2020-2023, driven by demand in advanced electronics and green energy leadership.

Recent breakthroughs in Nano-processing, chemical vapor deposition (CVD), and surface activation techniques have further boosted the conductivity, dispersibility, and lifespan of Conductive Mica Powder. Today’s top-tier products easily meet ISO/IEC standards for electronic use.

| Product Code | Type | Conductivity (Ω·cm) | Particle Size (μm) | Bulk Density (g/cm³) | pH | Moisture (%) | Surface Modification | Color | Standard |

|---|---|---|---|---|---|---|---|---|---|

| BF-CMP100 | Natural Mica | 1 × 10-2~1 × 10-1 | 25-45 | 0.32 | 7.3 | 0.4 | Ag Ion Doping | Silver Grey | IEC 61340 |

| BF-CMP200 | Synthetic Phlogopite | 5 × 10-3~6 × 10-2 | 10-30 | 0.29 | 7.8 | 0.2 | Graphene Coating | Dark Grey | ISO 9001 |

| BF-CMP300 | Calcined Mica | 2 × 10-3~3 × 10-2 | 5-20 | 0.26 | 7.1 | 0.3 | Carbon Black | Black | ANSI/ASTM D257 |

The production of Conductive Mica Powder at Baifeng Mining utilizes advanced equipment and certified protocols, ensuring each batch meets strict ISO 9001, IEC 61340, and ASTM standards.

Full technical outline here

| Vendor | Main Model | Conductivity (Ω·cm) | Key Feature | Testing Certification | Delivery Cycle |

|---|---|---|---|---|---|

| Baifeng Mining | BF-CMP200 | 5 × 10-3~6 × 10-2 | Graphene Surface, Ultra-fine Grade |

ISO 9001, IEC 61340 | 7-15 days |

| Lingshou Huayuan | HY-CP88 | 8 × 10-3~1.2 × 10-1 | Carbon Black | GB/T 9966, ISO | 18-22 days |

| Yamaguchi Mica | YM-CON680 | 3 × 10-3~5 × 10-2 | Silver Ion Doped | JIS K6911 | 20-30 days |

- OEM/ODM Options: Brand packing, custom modifications, and exclusive formulas for strategic partners.

- Pre-shipment full test reports; backed by ISO/IEC certificates.

- Technical consulting service from R&D (10+ years’ experience, 30+ international projects).

“After integrating Conductive Mica Powder into our PU dash and EV battery enclosure line, both static-related defect rates and downtime fell by 38%. The technical support and batch consistency from Baifeng Mining exceeded our benchmarks. Samples met both ISO 9001:2015 and RoHS test cycles.”

—Quality Engineering Director, EU Division

“The graphite-modified series ensured stable resistivity under high humidity and after multiple weathering cycles—outperforming conventional carbon black fillers in endurance and gloss retention.”

—R&D Lab Manager

-

Q: What is the base material of Conductive Mica Powder?

A: It is based on natural or synthetic muscovite/phlogopite mica, which are layered silicate minerals, subsequently treated for conductivity.

-

Q: How is bulk density relevant in application?

A: Bulk density (typically 0.26–0.34 g/cm³) reflects powder packing in a matrix, affecting mixing, flow, and mechanical properties in coatings and polymers.

-

Q: Which installation standards apply to ESD flooring with mica?

A: EN/IEC 61340-5-1, ANSI/ESD S20.20 and ASTM F150 standards generally apply, verifying surface and volume resistivity of finished flooring.

-

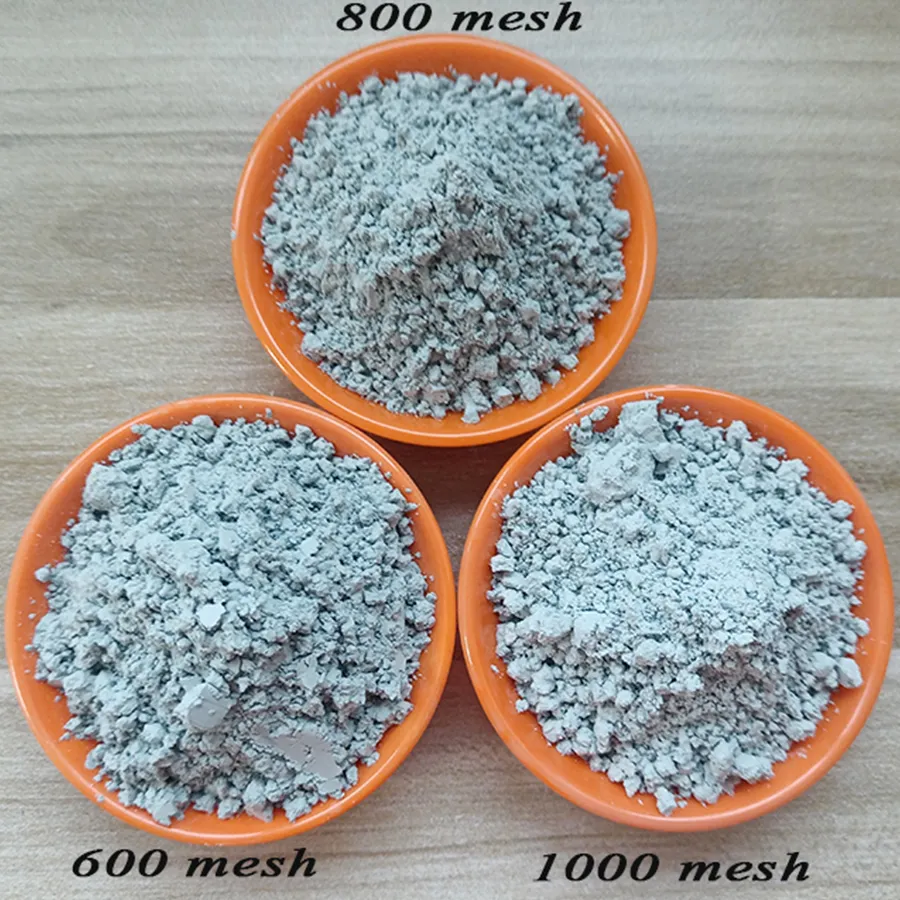

Q: What particle size grades are available?

A: 5μm to 63μm D50 typical; fine grades (

- Q: What test methods confirm conductivity?

A: Four-point probe (IEC 61340), DC resistivity, and ASTM D257 measurement standards are used for every batch.- Q: How is surface modification achieved?

A: By chemical vapor deposition or wet chemical reduction, using metals (Ag, Ni), graphene, or carbon black for enhanced electrical pathways.- Q: What is the delivery and support cycle?

A: Standard cycle within 7–15 days for stock models; OEM orders or large customizations 2–4 weeks. Technical support and after-sales provided throughout product life.11. Delivery & Warranty | Quality Assurance 12. Authoritative References & Further Reading - MarketsandMarkets: Mica Market Trends 2023

- IEEE Spectrum: Conductive Fillers in Composites

- ScienceDirect Journal — Case Studies: Mica-based Antistatic Coatings

- ISO/IEC Standard Documentation: ISO 61340 Series

- “Technical, Market, and Performance Aspects of Conductive Mica Powders” — Chemical Industry Forum:

Chemical Forums

- Q: What test methods confirm conductivity?

Related News