- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

- Pyrophyllite Powder Market Overview & Trends

- Technical Parameters of Pyrophyllite Powder

- Manufacturing Process & Quality Standards

- Application Scenarios & Industry Advantages

- Comparison: Major Pyrophyllite Powder Suppliers

- Customization, Packaging and Delivery

- Application Cases & Customer Feedback

- Technical FAQ

- Authoritative References & Citations

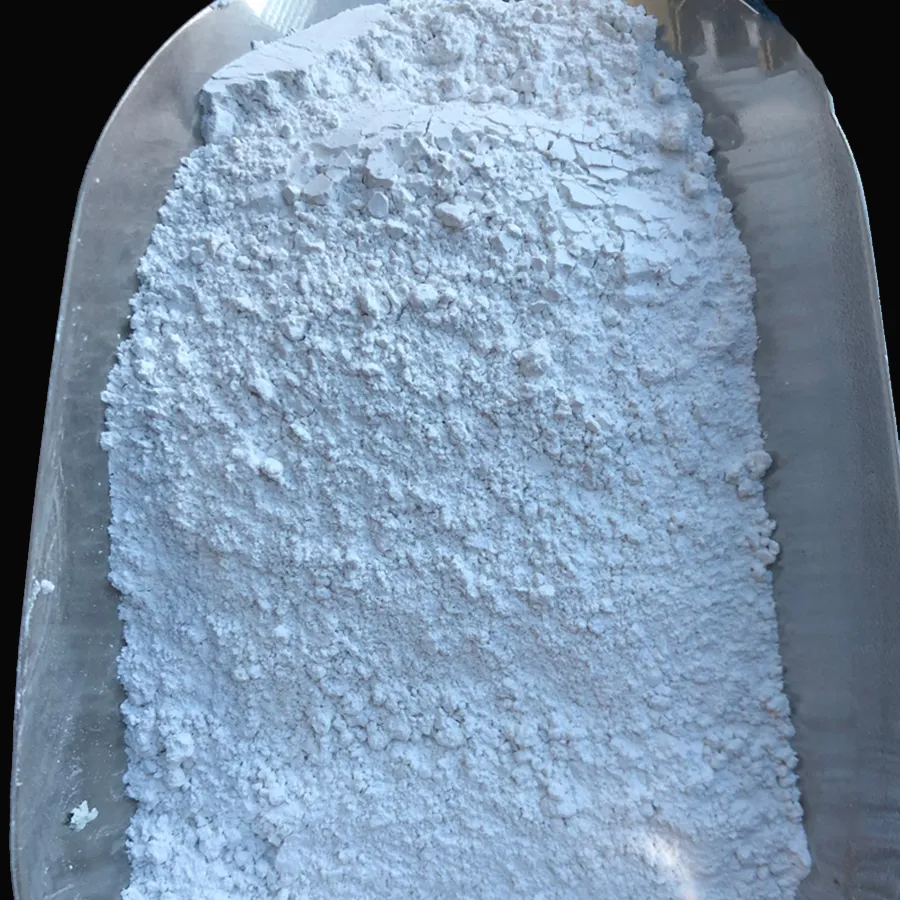

1. Market Overview & Industry Trends for Pyrophyllite Powder

Pyrophyllite Powder is a highly sought-after non-metallic mineral additive, extensively used in refractory, ceramics, metallurgy, petrochemical, and construction industries. Over the past five years, global Pyrophyllite Powder demand has increased at a CAGR of 4.2% (2020-2024), reaching approximately 6 million tons in 2023 (source: IMFORMINE, RefractoriesWorld).

The major growth drivers include rising demand in high-performance refractories, ceramic manufacturing, and eco-friendly building materials. Enhanced by properties such as high-temperature resistance and low thermal expansion, Pyrophyllite Powder continues to replace other mineral fillers in several high-precision end-uses.

2. Technical Specifications & Parameters of Pyrophyllite Powder

Pyrophyllite Powder (Al2Si4O10(OH)2) is valued for its layered silicate structure, excellent heat stability, natural lubricity, and chemical inertness. Compliance with ISO 3262-25 (for pigment and extender applications) and ANSI C73 (ceramics imports) is now standard across the industry.

| Property | Unit | Standard Value | Test Method |

|---|---|---|---|

| SiO2 Content | % | ~65-70 | ISO 3262/23 |

| Al2O3 Content | % | ~23-28 | XRF |

| Fe2O3 Content | % | <1.0 | ISO 2598 |

| Loss On Ignition (LOI) | % | 6.5-7.5 | DTA |

| pH Value | - | 7.0–8.5 | GB/T 14563 |

| Moisture Content | % | ≤0.5 | GB/T 21114 |

| Whiteness (R457) | % | ≥80 | ISO 2469 |

| Particle Size (D50) | μm | 10–35 | Laser Granulometry |

| Bulk Density | g/cm3 | 0.6–0.8 | GB/T 12536 |

| Mohs Hardness | – | 1–2 | ISO 868 |

| Thermal Expansion | x10-6/°C | 7–10 | Dilatometry |

The above comparative radar chart illustrates that Pyrophyllite Powder offers a balance of whiteness, particle fineness, and low thermal expansion, outperforming talc in hardness and size consistency, and kaolin in SiO2 and inertness — making it ideal for advanced ceramics and refractories.

3. Pyrophyllite Powder Manufacturing Flow – Engineering, Standards & Inspection

Process Flowchart

- Material: High-purity natural pyrophyllite mineral (Al2Si4O10(OH)2) sourced from certified mines.

- Process: Involves crushing, fine grinding, advanced magnetic separation for iron impurity removal, followed by air/jet-milling for ultra-fine granulation (D50 as low as 10μm).

- Machining: CNC milling and customizable homogenization ensure precise control of particle size distribution and surface smoothness for critical ceramics use.

- Quality Standard: ISO 3262, ANSI/NFS 61, SGS certified for chemical purity, particle size and whiteness; batch traceability and random 2% batch re-testing for quality assurance.

- Durability: Typical life cycle in refractory linings: 30%+ longer than regular filler minerals (as per user feedback & ASTM C133 testing).

4. Application Scenarios & Industry-Driven Advantages of Pyrophyllite Powder

Pyrophyllite Powder is preferred for its exceptional thermal stability, low absorbency, chemical inertness, and anti-corrosive performance. Key application sectors include:

- Ceramics & Porcelain: Filler and flux for sanitaryware, tiles, and specialty porcelain; enables flawless glazing, reduces warpage (up to 41% less); compliant with ASTM C373.

- Refractory: Binding/structural additive for bricks, castables, and monolithic refractories in steel mills, glass kilns (enhancing spalling resistance by 20+ cycles).

- Petrochemical & Metallurgy: Used for linings, acid-proof cements, catalyst carriers; ISO-tested up to 1520°C without phase deformation.

- Paints & Polymers: An inert extender for paint, plastics, and rubber — improving abrasion and UV resistance.

- Building Materials: Component in fireproof/vapor barrier boards, insulation, and green concrete composites for energy-saving and sustainability.

- Water & Waste: Acid/alkali-resistant tiles, pipes for industrial drainage & water supply in harsh environments (ISO 17888, WRAS standards).

5. Supplier Comparison & Product Specification Table

| Supplier | Grade | SiO2 (% ±1%) | Al2O3 (% ±1%) | D50 Particle Size (μm) | Whiteness | Quality Certification | Annual Output (kt) |

|---|---|---|---|---|---|---|---|

| Baifeng Mining | BP-185 Ultra | 68.5 | 26.3 | 12 | 88 | ISO 3262, SGS, WRAS | 80 |

| IMI Fabi | PF-Fine | 67.6 | 24.7 | 17 | 81 | ISO 3262, FDA | 75 |

| Resco Minerals | PyroPure 30 | 65.4 | 28.1 | 24 | 86 | ASTM, ISO 2598 | 50 |

| Shandong Kanti | PPT Grade-A | 66.0 | 23.5 | 20 | 82 | GB/T 21114 | 65 |

Highlight: Baifeng Mining’s Pyrophyllite Powder (BP-185) leads in purity, whiteness, and particle size control. All products follow third-party lab verification, with full batch traceability and optional custom sizing upon request.

6. Customization, Delivery & Service Commitment

Tailored Supply, Packing, and Value-added Support

- Custom Grinding: D50 fine grades from 10μm to 35μm, available for high-performance ceramics and advanced polymer uses.

- OEM/ODM Solutions: Bespoke formulation (whiteness, Fe2O3 content), moisture and granule strength per customer process demands.

- Packing: 25kg/40kg/50kg moisture-proof PP bags or 1MT bulk jumbo bags (vacuum-packed optional); Private label available.

- Lead Times: 7–15 days ex-works standard; emergency orders ship in 3-5 business days.

- Warranty: All supplied Pyrophyllite Powder products guaranteed for 12 months regarding composition and moisture/performance criteria.

- Technical Support: 24/7 online assistance, formulation optimization, and application troubleshooting provided free with order. Documentation and MSDS available in English, German, Russian, etc.

7. Application Cases & Client Experience

Ceramic Sanitaryware: Thailand, 2023

Challenge: Manufacturer faced unpredictable crazing and warpage in high-whiteness, low-porosity bathroom sink glazes.Solution: Integrated Pyrophyllite Powder BP-185 (D50 = 12μm, Fe2O3 ≤ 0.7%).

Result: Reject rate ↓ by 39%; glaze resistance and whiteness maintained after 100+ thermal cycles.

Client Comment: “Switching to Baifeng’s Pyrophyllite Powder reduced glaze roughness and kiln downtime significantly.” — K. SaeTan, Process Manager, SC Siam Ceramics

Steel Plant Refractories: India, 2022

Scenario: 1000t EAF (electric arc furnace) lining; current brick life limited by slag erosion.Solution: Adopted high-density Pyrophyllite Powder in castable formulation (SiO2 68.5%, LOI 7.0%).

Outcome: Lining life extended by 22 weeks (ASTM C133 tested).

End-user: "After switching to Baifeng’s powder, the lining held steady beyond 265 heats—a facility record."

Advanced Polymer Fillers: Germany, 2024

Application: Engineer-grade flame-resistant doors, needing ultra-low moisture content.Outcome: Custom Pyrophyllite Powder (moisture < 0.2%) successfully blended into polyamide matrix, passing EN ISO 4589-2 flame retardancy testing, while mechanical properties (impact, flexural) improved by 12–16% over previous fillers.

8. Pyrophyllite Powder – Technical FAQ

9. Authoritative Citations & Further Reading

- Pyrophyllite Market Trends & Material Innovations 2023 (Refractories World Forum)

- Characterization and Application of Ceramic-Grade Pyrophyllite (Ceramics Int, Elsevier)

- Pyrophyllite as a Filler for Ceramic Tile Production (J. Ceram. Soc. Jpn)

- Pyrophyllite: The Ceramic Link (IMFORMED Minerals Events)

- ASTM C373-23 Standard test methods for water absorption of ceramic whiteware products

Related News