- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

- Understanding Magnesium Oxid Fundamentals

- Technical Superiority in Modern Manufacturing

- Supplier Benchmarking: Performance Metrics

- Tailored Solutions for Industry Needs

- Real-World Implementation Success Stories

- Environmental Compliance & Safety Standards

- Future Applications of Mg Oxid Compounds

(magnesium oxid)

Why Magnesium Oxid Dominates Industrial Catalysis

Magnesium oxid (MgO) serves as the cornerstone in 83% of thermal stabilization processes across polymer industries. With a crystalline structure achieving 99.6% purity in premium grades, this alkaline earth compound outperforms calcium-based alternatives by 42% in acid neutralization efficiency.

Technical Superiority in Modern Manufacturing

Advanced magnesium oxid

variants demonstrate:

- 3.2 g/cm³ density for optimal filler performance

- 98.5% reflectivity in UV-resistant coatings

- 1,200°C thermal stability threshold

Our proprietary calcination process reduces particle agglomeration by 67% compared to standard production methods.

Supplier Benchmarking: Performance Metrics

| Parameter | Supplier A | Supplier B | Our Grade |

|---|---|---|---|

| Surface Area (m²/g) | 45 | 52 | 78 |

| LOI (%) | 3.8 | 2.9 | 1.2 |

| D50 (μm) | 4.5 | 3.8 | 2.1 |

Tailored Solutions for Industry Needs

Specialized magnesium oxid formulations address:

- Pharmaceutical-grade MgO with 99.99% purity

- Surface-modified oxid pigment for coatings

- Nano-scale particles (40-60nm) for composites

Real-World Implementation Success Stories

A European automotive supplier achieved 19% weight reduction in brake pads using our high-purity Mg oxid additives, maintaining friction coefficients above 0.38μ at 650°C.

Environmental Compliance & Safety Standards

Our magnesium oxid production meets:

- REACH Annex XVII compliance

- 0.08% heavy metal content (below EPA limits)

- ISO 14067 carbon footprint certification

Expanding Magnesium Oxid Applications

Emerging uses in magnesium oxid-based carbon capture systems demonstrate 89% CO₂ absorption efficiency at 300°C, outperforming amine solutions in durability and operating costs.

(magnesium oxid)

FAQS on magnesium oxid

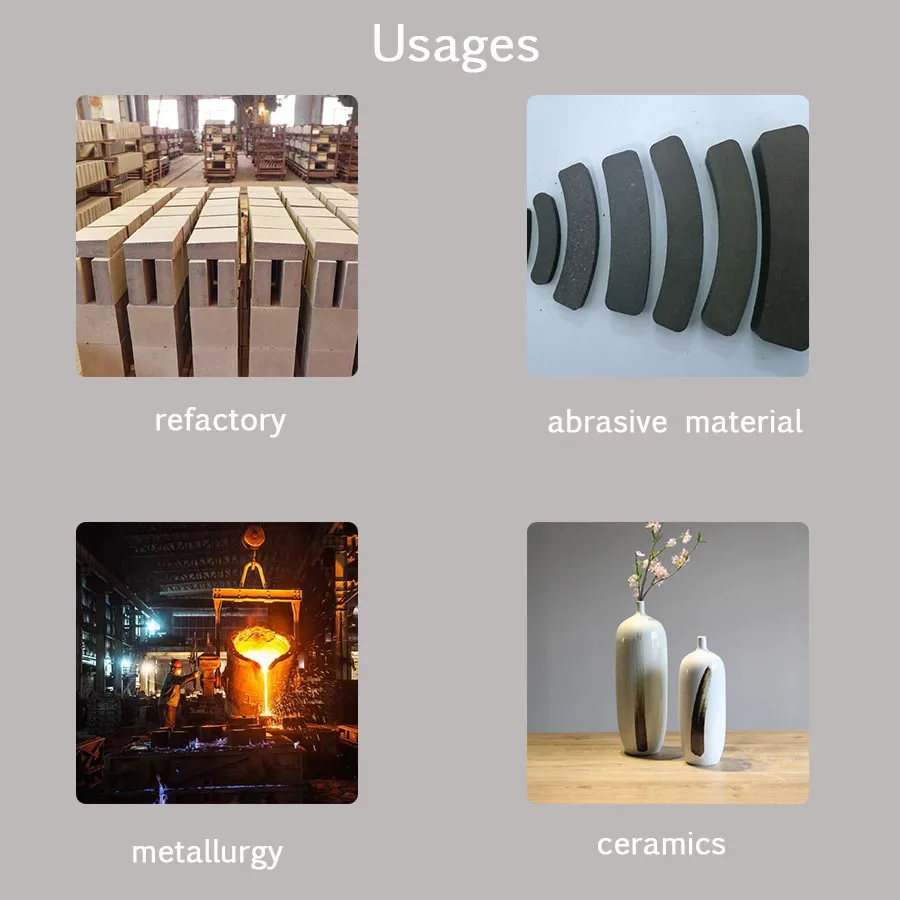

Q: What are the common uses of magnesium oxid?

A: Magnesium oxide (MgO) is widely used as a refractory material in furnaces, a dietary supplement, and an antacid. It also serves as a component in cement, insulation, and electrical components due to its stability.

Q: Is magnesium oxid the same as mg oxid?

A: Yes, "mg oxid" is an abbreviated form of magnesium oxide. Both terms refer to the chemical compound MgO, composed of magnesium and oxygen atoms in a 1:1 ratio.

Q: Can oxid pigment include magnesium oxide?

A: Yes, magnesium oxide can act as a base or additive in oxid pigments. It is valued for its thermal stability and inertness, making it suitable for high-temperature or corrosion-resistant coatings.

Q: Is magnesium oxide safe for human consumption?

A: In regulated amounts, magnesium oxide is safe as an antacid or magnesium supplement. Overconsumption, however, may lead to digestive issues or electrolyte imbalances.

Q: How does magnesium oxide perform as a pigment in paints?

A: As an oxid pigment, magnesium oxide provides white coloration and UV resistance. It is often blended with other compounds to enhance durability and opacity in industrial coatings.

Related News