- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

Understanding Calcium Oxide/Quicklime: An Essential Industrial Compound

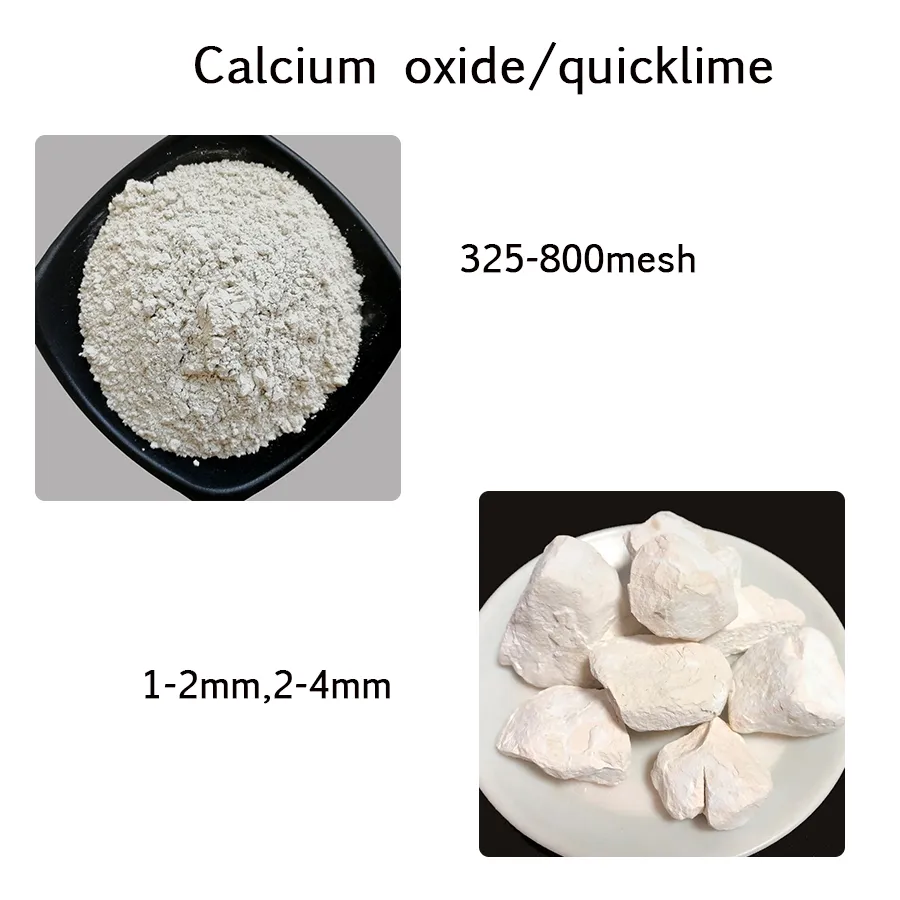

In the realm of industrial chemicals, Calcium Oxide/Quicklime, also commonly known as quicklime or burnt lime, stands as a cornerstone material due to its versatile chemical properties and extensive applications across numerous sectors. Derived primarily from the calcination of limestone, quicklime is a white, caustic, alkaline, crystalline solid that plays a pivotal role in processes ranging from metallurgy and construction to environmental management and chemical synthesis. Its high reactivity with water, releasing significant heat in an exothermic process known as slaking, makes it an invaluable reagent for pH adjustment, desiccation, and purification. Understanding the nuanced characteristics of quicklime, including its various grades and performance metrics, is crucial for optimizing industrial operations and ensuring the efficiency and safety of diverse manufacturing and processing activities. The global market for quicklime continues to expand, driven by robust demand from the steel industry, infrastructure development, and growing concerns for water and wastewater treatment, underscoring its enduring importance in modern industrial landscapes. Its cost-effectiveness combined with potent chemical activity positions it as a preferred choice over alternative materials in many critical applications, contributing to sustainable and economically viable solutions worldwide.

The manufacturing process of industrial-grade Calcium Oxide/Quicklime involves a precise and energy-intensive thermal decomposition of calcium carbonate (CaCO₃), typically found in limestone, dolomite, or marble, within specialized kilns. This process, known as calcination, occurs at temperatures typically ranging from 900°C to 1200°C (1650°F to 2200°F), driving off carbon dioxide (CO₂) and leaving behind a highly reactive product. Common manufacturing technologies include rotary kilns, vertical shaft kilns, and fluidized bed kilns, each offering distinct advantages in terms of energy efficiency, product quality, and capacity. The raw material, limestone, is carefully selected for its purity, with lower impurity levels translating into higher quality quicklime. After calcination, the resulting clinker, or burnt lime, undergoes crushing, grinding, and screening to achieve specific particle sizes and distributions, catering to various end-use requirements. This meticulous control over material sourcing and processing ensures that the final quicklime product meets stringent industry standards such as ASTM C110 for physical testing of quicklime and hydrated lime, or ISO 9001 for quality management systems, guaranteeing consistent performance and reliability in demanding industrial applications. The material properties of quicklime, characterized by high alkalinity and strong desiccant action, are meticulously controlled throughout the production cycle to maximize its efficacy in diverse applications, from pH modification in water treatment to acting as a powerful flux in metallurgical processes.

Technical Parameters and Specifications of High-Quality Quicklime

The performance of Calcium Oxide/Quicklime in industrial applications is critically dependent on its specific technical parameters and chemical composition, which are meticulously controlled during production. Key parameters include the purity of calcium oxide (CaO content), reactivity, particle size distribution, bulk density, specific gravity, and the content of impurities such as silica (SiO₂), alumina (Al₂O₃), iron oxide (Fe₂O₃), and magnesium oxide (MgO). High-purity quicklime, often exceeding 90-95% CaO, is particularly sought after in sensitive applications like steelmaking, where its consistent quality directly impacts process efficiency and end-product purity. Reactivity, measured by the temperature rise and time taken for a specific amount of quicklime to react with water (slake), is another vital characteristic, influencing its effectiveness in water treatment and chemical reactions. For instance, highly reactive quicklime is preferred for rapid pH adjustment and coagulation processes in municipal wastewater treatment. Particle size plays a significant role in handling, transport, and dissolution rates; fine quicklime powders offer greater surface area for reactions, while coarser granules are more suitable for applications requiring controlled dissolution or better flowability. Compliance with international standards, such as ASTM C977 for quicklime for environmental applications or other relevant ISO/ANSI standards for industrial chemicals, assures users of the product's quality and suitability for specific uses. Our product typically adheres to and often exceeds these standards, offering exceptional consistency and performance reliability for our B2B partners, validated through rigorous in-house quality control and third-party laboratory testing, reinforcing our commitment to delivering superior industrial materials.

| Parameter | Unit | Typical Value Range | Testing Method (e.g.) |

|---|---|---|---|

| Calcium Oxide (CaO) Purity | % | 90 - 98 | ASTM C25 (Chemical Analysis) |

| Magnesium Oxide (MgO) | % | 0.5 - 2.5 | ASTM C25 |

| Silicon Dioxide (SiO₂) | % | 0.5 - 2.0 | ASTM C25 |

| Aluminium Oxide (Al₂O₃) | % | 0.2 - 1.0 | ASTM C25 |

| Iron Oxide (Fe₂O₃) | % | 0.1 - 0.5 | ASTM C25 |

| Loss on Ignition (LOI) | % | 0.5 - 2.0 | ASTM C25 |

| Reactivity (Slaking Rate) | °C / minutes | >30°C in | ASTM C110 (Slaking Test) |

| Available Lime Index | % | >85 | ASTM C110 |

Beyond its intrinsic chemical properties, the physical characteristics of quicklime significantly influence its utility and application-specific performance. Particle size distribution, for instance, determines the surface area available for reaction and the speed at which quicklime dissolves or reacts within a given system. Finer quicklime typically offers faster reactivity due to a larger cumulative surface area, making it ideal for processes requiring rapid pH adjustment or immediate chemical action, such as in certain chemical manufacturing or rapid soil stabilization techniques. Conversely, coarser grades of quicklime might be preferred for applications where a slower, more controlled release of alkalinity is desired, or where dust generation needs to be minimized during handling. Bulk density, which refers to the mass of quicklime per unit volume in its loose state, affects storage requirements and transportation costs, with higher bulk density generally indicating more efficient use of space. Specific gravity, or the ratio of the density of quicklime to the density of water, is also a critical parameter for engineers designing dosing and mixing systems. The longevity and reliability of quicklime in its intended application are also considerations, particularly in civil engineering where its role in soil stabilization can impact the lifespan of infrastructure projects. Adherence to strict quality control protocols throughout the production chain, including comprehensive laboratory analyses for particle size, bulk density, and specific gravity, ensures that each batch of quicklime consistently meets the demanding specifications required by diverse industries, reinforcing its reputation as a dependable and high-performing industrial additive.

Versatile Applications and Core Advantages of Quicklime Across Industries

The pervasive utility of quicklime extends across an incredibly diverse array of industrial sectors, each leveraging its unique chemical and physical properties for critical operations. In the metallurgical industry, particularly steel production, quicklime serves as a primary fluxing agent, reacting with impurities such as silica, alumina, and phosphorus to form slag, thus purifying the molten metal and extending the lifespan of refractory linings. Its application here leads to cleaner steel and improved process economics, making it indispensable for both basic oxygen furnaces (BOF) and electric arc furnaces (EAF). In environmental applications, quicklime is crucial for water and wastewater treatment, where its strong alkaline nature allows for effective pH adjustment, coagulation of suspended solids, and removal of heavy metals, phosphates, and fluorides. It also plays a vital role in sludge stabilization, preventing putrefaction and reducing odor. For the construction sector, quicklime is used for soil stabilization, especially in clay-rich soils, where it reacts to improve load-bearing capacity, reduce plasticity, and enhance workability, proving indispensable for road construction and foundation preparation. Furthermore, it is a key component in the production of aerated concrete and various building materials. In the chemical industry, quicklime acts as a desiccant, a drying agent, and a raw material for producing other calcium compounds. Its broad applicability underscores its economic significance and role in promoting sustainability through efficient resource utilization and pollution control across these varied industrial landscapes, exhibiting significant advantages in terms of cost-effectiveness and process optimization.

Beyond its primary applications, Calcium Oxide/Quicklime offers distinct technical advantages that position it as a superior choice compared to alternative materials in numerous industrial processes. One of its most significant benefits is its high alkalinity, which enables efficient neutralization of acidic waste streams and precise pH control in chemical reactions. This characteristic makes it more effective and often more economical than other alkaline agents like caustic soda in many scenarios. Its strong desiccating properties are invaluable for moisture removal, serving as a powerful drying agent in industrial gases and certain chemical syntheses, contributing to product quality and preventing equipment corrosion. In the context of the petrochemical industry, quicklime can be used for desulfurization in flue gas treatment, absorbing sulfur dioxide to mitigate air pollution, showcasing its environmental benefits. In the mining sector, it is utilized for flotation, adjusting pulp pH for optimal mineral recovery, and for the neutralization of acidic mine drainage, highlighting its role in environmental remediation and resource efficiency. The energy efficiency gains achieved by using quicklime, particularly in steelmaking processes where it reduces energy consumption by facilitating faster slag formation, represent substantial operational savings. Its non-toxic nature (when handled properly) and widespread availability also contribute to its preferred status. The extensive track record of quicklime's successful deployment across diverse industries, coupled with continuous innovation in its production and application methods, confirms its status as an economically advantageous and environmentally responsible material, offering robust solutions for complex industrial challenges and consistently delivering superior performance.

Custom Solutions, Manufacturer Comparison, and Application Case Studies

Selecting the right quicklime supplier requires a thorough evaluation of several factors beyond just price, including product consistency, purity, reactivity, logistical capabilities, and the ability to provide tailored solutions. While many manufacturers offer standard grades of quicklime, leading providers distinguish themselves by offering customized solutions engineered to meet the precise demands of specific industrial applications. This might involve adjusting particle size distribution, modifying reactivity profiles, or ensuring ultra-low impurity levels for highly sensitive processes. For example, a steel mill might require a high-reactivity quicklime with minimal silica content to optimize slag formation and reduce refractory wear, whereas a water treatment plant might prioritize a specific particle size for ease of dosing and rapid dissolution. Reputable manufacturers also emphasize robust quality control, often adhering to international standards like ISO 9001 and possessing comprehensive in-house testing facilities to guarantee product specifications. Furthermore, a manufacturer's technical support capabilities, including assistance with storage, handling, and application optimization, are crucial for long-term partnerships. Our commitment to deep customer engagement allows us to develop quicklime solutions that are not just products but integral components of our clients' operational success, ensuring maximum efficiency and adherence to all project-specific requirements, a testament to our expertise and customer-centric approach in the B2B quicklime market.

Our company's long-standing experience in the quicklime industry is exemplified by numerous successful application case studies, demonstrating our capability to deliver high-performance Calcium Oxide/Quicklime solutions that address complex industrial challenges. For instance, in a major municipal wastewater treatment plant facing issues with excessive sludge volume and high heavy metal concentrations, our customized high-purity quicklime, delivered with precise particle sizing, significantly reduced sludge quantity by over 30% through improved dewatering and effectively lowered heavy metal levels to within discharge limits. This solution not only optimized their operational costs but also enhanced their environmental compliance, showcasing the practical benefits of tailored product specifications. Another compelling case involved a large-scale steel manufacturer seeking to reduce lime consumption and furnace cycle times. By implementing our high-reactivity quicklime, optimized for their specific BOF process, they achieved a 15% reduction in lime usage per ton of steel and decreased tap-to-tap times, leading to substantial productivity gains and energy savings. These real-world examples underscore our ability to provide value-added quicklime solutions that translate into tangible improvements in efficiency, cost-effectiveness, and environmental performance for our B2B partners, solidifying our position as an authoritative and trustworthy supplier in the global quicklime market.

| Quicklime Grade | Key Characteristics | Typical Applications | Advantages |

|---|---|---|---|

| High-Calcium Quicklime | CaO > 95%, low impurities, high reactivity | Steelmaking, chemical production, flue gas desulfurization | Maximum efficiency in purification, reduced consumption |

| Dolomitic Quicklime | Contains significant MgO (e.g., 30-40%), lower CaO | Refractory applications, glass manufacturing, agriculture | Enhanced refractory performance, source of magnesium |

| Environmental Grade Quicklime | Optimized reactivity and particle size for specific environmental processes | Water/wastewater treatment, sludge stabilization, acid mine drainage | Efficient pollutant removal, pH control, reduced sludge volume |

| Construction Grade Quicklime | Specific particle sizes and reactivity for soil stabilization | Soil stabilization (roads, foundations), asphalt production | Improved soil properties, increased bearing capacity, reduced plasticity |

Ensuring Trustworthiness: FAQ, Delivery, and Customer Support

Establishing trustworthiness in the B2B quicklime market hinges on transparent communication, reliable logistics, and unwavering customer support. Our commitment to clients is reinforced by clear delivery schedules, comprehensive quality assurance, and robust post-sales service. We understand that timely delivery of quicklime is critical for maintaining seamless industrial operations, and our advanced supply chain management systems are designed to ensure just-in-time delivery, minimizing inventory costs for our partners. We offer flexible packaging options, from bulk deliveries in specialized trucks and railcars to various sizes of bags (e.g., 25kg, 1-ton bulk bags) to accommodate diverse client needs and handling capabilities. Our standard delivery cycle is typically within 7-14 business days for major regions, with expedited options available upon request for urgent requirements. Furthermore, our products come with a comprehensive quality guarantee, ensuring that all quicklime supplied meets the agreed-upon technical specifications and relevant industry standards for a specified period after delivery, providing clients with peace of mind regarding product integrity and performance. This commitment to reliability is a cornerstone of our service, cultivated through years of experience and validated by strong, long-term relationships with leading industrial players, reflecting our dedication to upholding the highest standards of trust and operational excellence in all client engagements.

Our comprehensive customer support extends beyond product delivery, encompassing technical assistance, application guidance, and troubleshooting to ensure optimal performance of our Calcium Oxide/Quicklime in your operations. We offer expert consultations for product selection, dosage optimization, and system integration, leveraging our deep industry knowledge and extensive experience. Our dedicated support team is available to address any inquiries regarding product specifications, safety protocols, or logistical arrangements, ensuring a seamless experience from initial consultation to long-term partnership. We believe in building enduring relationships with our clients by providing not just high-quality products, but also reliable and responsive support. This commitment to service excellence, combined with our rigorous quality control and adherence to international standards, underpins the trust that our global clients place in us as their preferred quicklime supplier. Our proactive approach to client engagement and problem-solving differentiates us in the market, making us a dependable partner for all your quicklime needs, reflecting our dedication to client success and continuous improvement.

References

- Boynton, R. S. (1980). Chemistry and Technology of Lime and Limestone (2nd ed.). John Wiley & Sons.

- Miller, D. B. (2000). The Lime Handbook: A Guide to the Production and Use of Lime and Dolomite. National Lime Association.

- Lear, G. (2014). Calcium Oxide. In K. Barbalace (Ed.), Chemical Database. The University of Bristol.

- ASTM International. (Various). ASTM Standards C25, C110, C977: Standard Test Methods and Specifications for Hydrated Lime and Quicklime.

Related News