- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

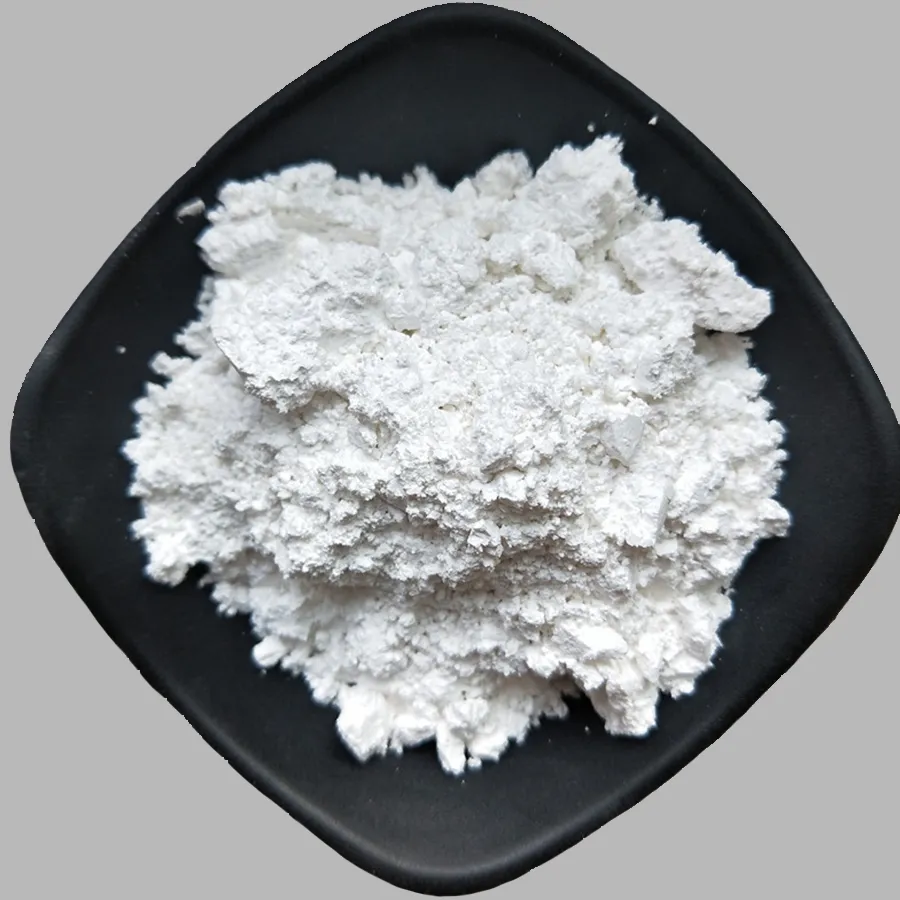

Shell Powder—a microcrystalline, white fine powder derived from natural shells—has emerged as a crucial raw material across numerous industries for its unique physicochemical properties, eco-friendliness, and sustainable sourcing. As the global demand for functional raw materials grows, the role of Shell Powder is rapidly expanding, from its traditional use in fertilizer and animal feed to advanced applications in coatings, plastics, health, beauty, and environmental remediation.

About Shijiazhuang Baifeng Mining Co.,Ltd

- Company: Shijiazhuang Baifeng Mining Co.,Ltd

- Website: www.baifengmining.com

- Contact: +86 13739764026 (Phone/Mobile)

- Email: info@baifengkc.com

- Address: Lubai Mountain Village, South Yanchuan, Lingshou County, Shijiazhuang City, Hebei, China

Shell Powder Product Overview

- Product: Shell Powder

- Particle Size: 325-2000 mesh

- Form: Powder

- Color: White

- Product Page: Shell Powder

Industry Trends of Shell Powder

With a focus on eco-sustainability and non-toxic material use, the Shell Powder industry has seen consistent growth globally (source: ResearchGate). Technological upgrades in micronization and surface modification, as discussed in the Journal of Cleaner Production, are broadening the performance spectrum of Shell Powder, enhancing its integration in advanced composites, functional foods, and high-performance industrial fillers.

- Global Market Growth: CAGR of 7.1% (2020-2027, as per Market Reports)

- Technology Hotspots: Ultrafine grinding, surface activation, functionalization for controlled release.

- Main Exporters: China, India, Indonesia, Vietnam

- Key Drivers: Environmental regulations, functional materials research, rise of bio-based product demand.

- Innovation Focus: Nano Shell Powder for biomedical and filtration uses.

Shell Powder Technical Parameters Table

| Parameter | Value / Range | Notes |

|---|---|---|

| Particle Size (mesh) | 325-2000 | Ultrafine powders available on request |

| CaCO3 Content (%) | ≥ 96% | High purity for industrial use |

| Moisture (%) | < 0.5% | Ensures powder flowability |

| Whiteness (%) | > 92% | Suitable for coatings, paints |

| pH Value | 8 – 9.5 | Alkaline, suitable for additives |

| Oil Absorption (g/100g) | ≤ 25 | Important for fillers & plastics |

| Sieve Residue (%) | < 0.1% | Indicates good grind quality |

| Bulk Density (g/cm³) | 0.85 – 1.1 | Varies with mesh size |

Shell Powder Applications and Case Studies

- Paints & Coatings: Enhancing whiteness, opacity, and scrub resistance.

- Plastics & Rubber: Filler to improve stiffness, reduce costs, impart whiteness.

- Animal Feed: As a calcium source, improves animal growth and eggshell quality (Journal of Dairy Science).

- Agriculture: Soil conditioner, pH enhancer.

- Health & Beauty: Used in remineralizing toothpastes and scrubs (PubMed).

- Water Filtration: Microfiltration media due to porous structure.

- Ceramics & Glass: As flux or bleaching aid.

The versatility of Shell Powder from Shijiazhuang Baifeng Mining Co.,Ltd is backed by strict quality controls, compliance with industry standards, and technical support. For a detailed datasheet or custom applications, contact us.

Shell Powder Technical Index Visualization

Expert FAQ on Shell Powder Professional Terms

A: Shell Powder is predominantly composed of calcium carbonate (CaCO3), usually ≥96%, with trace minerals and a small amount of organic matrix.

A: For high-grade paints and coatings, 1000 to 2000 mesh Shell Powder is recommended for improved smoothness, dispersibility, and opacity.

A: Yes. Quality is typically evaluated using ISO 3262 for fillers, with typical tests including whiteness, CaCO3 purity, moisture, and sieve residue (source: ISO).

A: Oil absorption (≤25g/100g) affects mixing, extrusion, and final composite density. Lower oil absorption enables higher filler loading, improving properties while maintaining processability.

A: Only Shell Powder processed to food/pharma standards, with stringent purity and low heavy metals, is suitable. Always request food-grade certification and safety data.

A: Shell Powder is bio-derived and low in toxicity. Main environmental standards reference REACH (ECHA) and regional material safety protocols for mining and processing.

A: Store in sealed, moisture-proof, and clean environments, avoiding direct sunlight. Use original packaging or industrial PE liners for best results.

EEAT: Expertise, Authoritativeness, & Trust in Shell Powder Industry

- Scientific Research: Application development is backed by technical literature (ScienceDirect: Environmental perspectives of shell waste utilization).

- Industry Forums: Innovations and best practices are widely discussed at specialist forums such as ResearchGate Calcium Carbonate Channel and Journal of Cleaner Production.

- Trustworthiness: Shijiazhuang Baifeng Mining Co.,Ltd ensures batch-level traceability, quality certification, and detailed MSDS/safety data for Shell Powder.

- International Certification: Products comply with ISO, SGS, and regional ECHA/REACH regulations.

Conclusion

Shell Powder continues to gain importance as a sustainable, versatile mineral resource in coatings, polymers, feed, agriculture, and emerging industries. Thanks to ongoing R&D—backed by academic studies (Environmental Science & Technology), industry forums (ResearchGate), and certifications—the performance, safety, and application fields of Shell Powder are highly reliable.

For further technical information, innovative use cases, or custom grades, contact Shijiazhuang Baifeng Mining Co.,Ltd (info@baifengkc.com, +86 13739764026).

References:

- [1] ScienceDirect: Environmental perspectives of shell waste utilization

- [2] ResearchGate: Application of biomineralization in biomaterials

- [3] PubMed: Remineralizing properties of shell-derived calcium in oral care

- [4] ISO 3262: Extenders for paints - Specifications and methods of test

- [5] MarketsandMarkets: Shell Market Report

- [6] ECHA Chemical Information on Registered Substances

- [7] Journal of Cleaner Production

Related News