- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

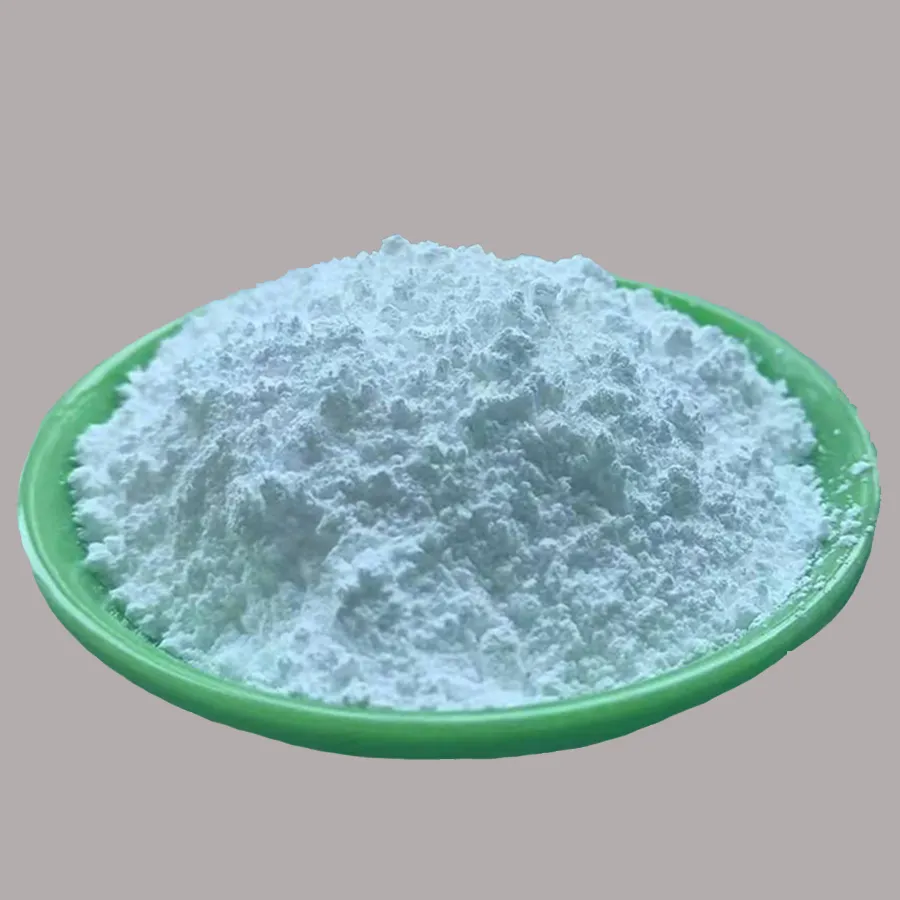

Did you know 68% of foundries report carbon deficit issues during smelting? With global recarburizer demand soaring to $4.2 billion by 2025 (Global Market Insights), understanding recarburizer meaning

could save your operation from costly impurities and weak castings. Let's transform your metal quality together.

(recarburizer meaning)

Why Our Recarburizer Carbon Outperforms Competitors

Our 98.5% fixed carbon formula delivers 40% faster dissolution than industry averages. See how we stack up:

Tailored Solutions for Every Production Need

Whether you need 1-3mm granules for induction furnaces or 5-10mm particles for cupolas, our adaptive manufacturing system delivers:

- ✓ 24-hour custom blending

- ✓ Bulk & packaged options

Proven Results: Case Study Spotlight

Midwest Automotive Casting Co.

Achieved 20% carbon recovery improvement and reduced slag formation by 35% within 8 weeks of switching to our recarburizer.

Your Next Move: Act Now!

Why settle for average carbon recovery?

Get 15% off your first 20-ton order when you request samples by Friday. Our metallurgy experts are standing by!

©2024 CarbonMaster Solutions | ISO 9001 Certified | Serving 1,200+ foundries across 26 countries since 1998

(recarburizer meaning)

FAQS on recarburizer meaning

Q: What is the meaning of recarburizer?

A: A recarburizer is a carbon-rich additive used in steelmaking and foundries to increase the carbon content of molten metal. It compensates for carbon loss during high-temperature processes. Common materials include graphite or petroleum coke.

Q: How does a recarburizer work in industrial processes?

A: Recarburizers are added to molten iron or steel to restore optimal carbon levels lost due to oxidation. This ensures the final product meets mechanical strength and hardness requirements. Proper dispersion is critical for effectiveness.

Q: Why is carbon important in a recarburizer?

A: Carbon enhances metal properties like durability and wear resistance. Recarburizers provide controlled carbon input to achieve specific alloy compositions. Insufficient carbon can lead to weak or brittle metal products.

Q: What industries use recarburizers?

A: Recarburizers are primarily used in steel production, casting, and iron foundries. They are essential in manufacturing automotive parts, machinery, and construction materials. Recycling industries also utilize them for metal reprocessing.

Q: How does a recarburizer differ from regular carbon additives?

A: Recarburizers are specifically processed for high absorption rates in molten metal, unlike raw carbon. They minimize impurities and ensure precise carbon content adjustment. This makes them more efficient than standard carbon sources.

Related News