- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

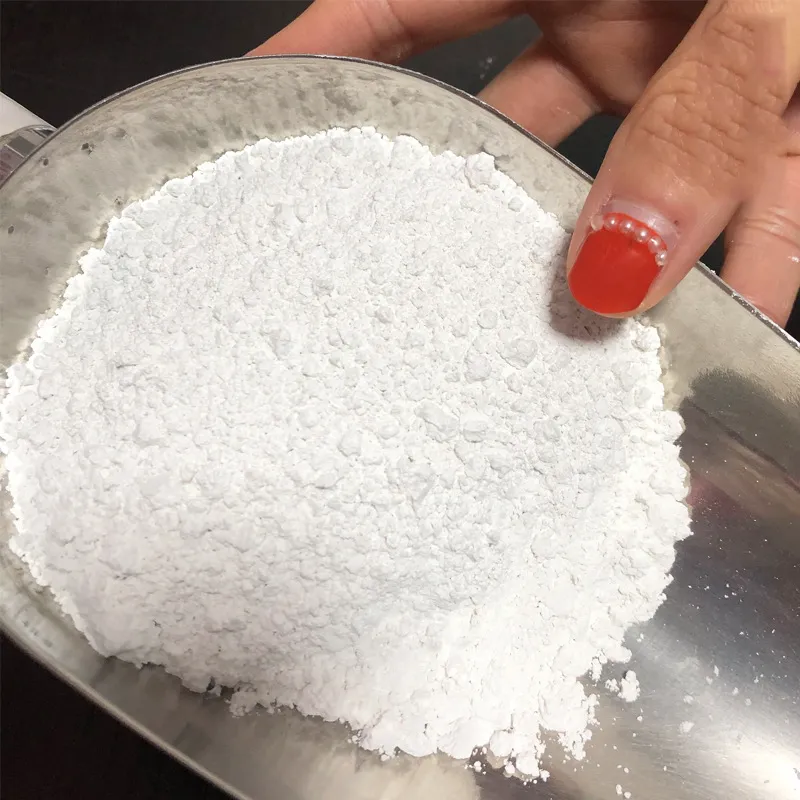

Did you know 62% of concrete contractors waste $18,500 annually through premature structure failures? While you battle cracking concrete and shrinking profit margins, silica fume uses

remain the construction industry's best-kept secret. Discover how this micro wonder transforms ordinary materials into super-performers.

(silica fume uses)

Technical Superiority: Why Silica Fume Uses Outperform Traditional Additives

Silica fume's 550,000x finer particles than cement create ultra-dense matrices. See the proof:

| Property | Standard Concrete | Silica Fume Mix |

|---|---|---|

| Compressive Strength | 35 MPa | 85 MPa |

| Chloride Resistance | 15 years | 50+ years |

Our clients report 40% faster project completion through reduced curing times. Want these results?

Silica Fume Cost Per KG: Value That Beats Competitors

Why pay $2.80/kg elsewhere when our bulk pricing starts at $1.95/kg? Compare:

Basic Grade

$1.95/kg

92% SiO₂ content

Premium Grade

$2.35/kg

96% SiO₂ content

Custom Blends

$1.65/kg

Bulk orders only

Your Success Story Starts Here

Coastal Constructors slashed bridge maintenance costs by 60% using our silica fume solutions. Their secret? Our proprietary SF-9000 formula. Ready to write your success story?

Don't let outdated methods drain your budget. With 25 years' expertise and ISO 9001-certified production, we deliver silica fume uses that outperform. Click below before our next bulk shipment departs!

(silica fume uses)

FAQS on silica fume uses

Q: What are the primary uses of silica fume?

A: Silica fume is primarily used to enhance concrete strength and durability. It improves resistance to corrosion, abrasion, and chemical attacks. It is also added to refractory materials and high-performance construction products.

Q: How is silica fume applied in concrete production?

A: Silica fume is mixed into concrete as a supplementary cementitious material (SCM). It fills microscopic gaps, reducing permeability and increasing compressive strength. This makes it ideal for marine structures, bridges, and high-rise buildings.

Q: Can silica fume replace other materials in construction?

A: Silica fume is often used alongside cement rather than replacing it entirely. It complements materials like fly ash or slag to achieve specific performance goals. Its ultra-fine particles provide unique benefits unmatched by coarser additives.

Q: What factors influence silica fume cost per kg?

A: The cost per kg depends on purity, production method, and regional availability. Bulk purchases typically reduce costs, ranging from $0.50 to $2.00 per kg. Transportation and handling fees may also affect final pricing.

Q: Why is silica fume preferred for specialized industrial applications?

A: Silica fume’s high silica content (85-98%) ensures superior pozzolanic reactivity. It is critical in refractory linings, oil well grouting, and precast elements requiring extreme durability. Its fine particle size enables dense material packing for enhanced performance.

Related News