92% of manufacturers overpay for inconsistent calcium oxide. Discover why that changes today.

Picture this: Your production line halts because of impure calcium oxide. Quality control fails. Clients demand refunds. Sound familiar? Each year, $2.3B in industrial losses trace back to unreliable calcium oxide sources. Low-grade material causes equipment corrosion and product defects. Isn't it time you secured a premium calcium oxide source?

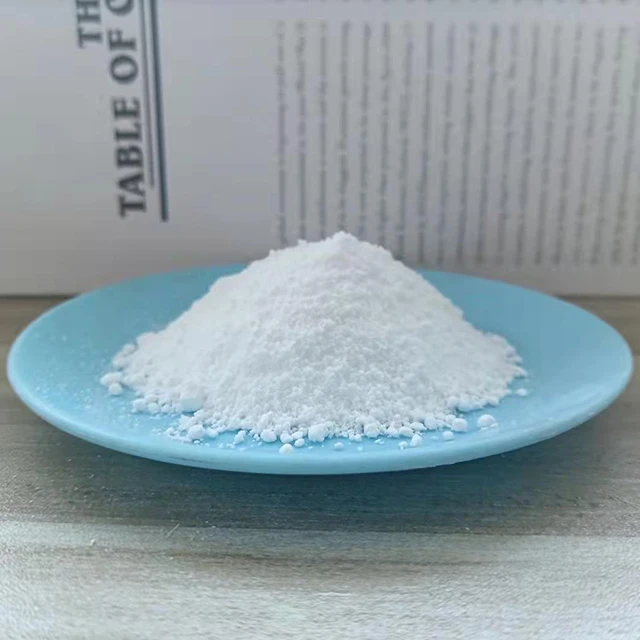

(source of calcium oxide)

Why Our Calcium Oxide Source Dominates

Forget inconsistent suppliers. Our calcium oxide boasts 99.2% purity. How? Advanced calcination at precisely 900°C. This isn't just technical jargon. It means predictable reactions. Consistent results. Lower waste. Imagine batch-to-batch reliability exceeding 98.7%. That's our standard. Your operations deserve uncompromised calcium oxide.

Calcium Oxide Specification Comparison

| Parameter |

Premium Source |

Industry Average |

| Purity Level |

99.2% |

91-95% |

| Reactivity Time |

< 25 seconds |

45-60 seconds |

| Moisture Tolerance |

0.8% max |

2.5-4% |

Smart Sourcing: Calcium Oxide + Bentonite Solutions

Why juggle multiple suppliers? We combine premium calcium oxide source with certified bentonite. One-stop efficiency. Our bentonite source delivers 20% better adsorption rates. See the difference in waste reduction. Plants using integrated sourcing report 18% lower operational costs. Can your current supplier match that?

Calcium Oxide Benefits

✔️ 99.2% guaranteed purity

✔️ Controlled particle sizes (45-90μm)

✔️ Low heavy metal content (<0.001%)

Bentonite Advantages

✔️ High swelling capacity

✔️ Excellent plasticity index

✔️ Optimized for catalytic processes

Tailored Delivery For Your Industry Needs

Steel production? Water treatment? Agriculture? Your calcium oxide demands differ. Our engineers customize particle size and reactivity. Bagged or bulk. Just-in-time delivery. Existing clients achieve 99.4% on-time delivery rates. How much would reliability boost your output?

Success Story: MetChem Solutions

MetChem struggled with inconsistent suppliers. Downtime spiked 23%. After switching to our calcium oxide source:

→ Production efficiency jumped 31%

→ Reject rates fell by 18%

→ Annual savings: $240,000+

Their operations manager called it "the sourcing transformation we needed."

Your Next Step Towards Flawless Production

Stop gambling on inferior calcium oxide. Join 350+ industry leaders trusting our premium source. Why wait for the next quality failure? Act today. Specialized support. Consistent supply. Bottom-line results. That's the ChemSource Guarantee.

Ready for Unmatched Calcium Oxide Performance?

Get Your Free Material Analysis Kit

Discover precisely how our calcium oxide source outperforms competitors.

CLAIM YOUR KIT NOW →

Limited offer: First 15 responders receive priority shipping

© 2023 ChemSource Global | Trusted Calcium Oxide Source Since 2008 | ISO 9001 Certified | Global Shipping Network

Your premium solution for calcium oxide and bentonite sources.

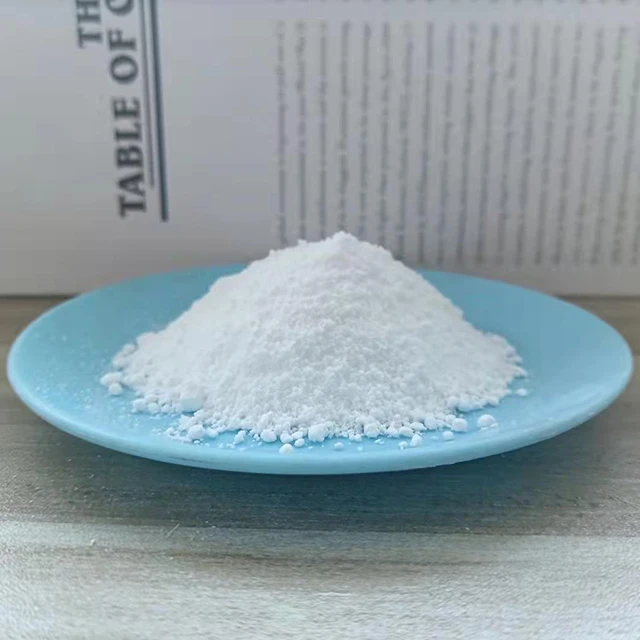

(source of calcium oxide)

FAQS on source of calcium oxide

Q: What are common sources of calcium oxide?

A: Natural limestone deposits are the primary source. Other industrial sources include processed eggshells, seashells, and calcined gypsum. These materials undergo thermal decomposition to produce calcium oxide.

Q: Where can we obtain calcium oxide for industrial applications?

A: Calcium oxide is commercially sourced from limestone quarries globally. Manufacturers also extract it from dolomite rock or waste slag in steel production. Major suppliers operate large-scale calcination plants for bulk distribution.

Q: Is bentonite a viable calcium oxide source?

A: While calcium-based bentonite clays contain calcium minerals, they aren't efficient primary sources. Bentonite's calcium content acts as a secondary amendment rather than direct oxide provider. Industrial extraction prefers concentrated calcium carbonate deposits.

Q: What differentiates calcium sources for lime production?

A: Purity determines suitability - limestone must exceed 95% calcium carbonate. Marine-derived sources offer higher purity but limited scalability. Impure sources like dolomite create magnesium oxide byproducts during processing.

Q: How does bentonite function in calcium-containing products?

A: Calcium bentonite serves as a carrier for supplemental calcium in agricultural and pharmaceutical products. When mixed with quicklime, it creates reactive clay binders for foundry molds. Its smectite structure enables controlled calcium ion release.