- Afrikaans

- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- Danish

- Dutch

- English

- Finnish

- French

- Galician

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Khmer

- Rwandese

- Korean

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Malay

- Maltese

- Mongolian

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Ukrainian

- Vietnamese

- Welsh

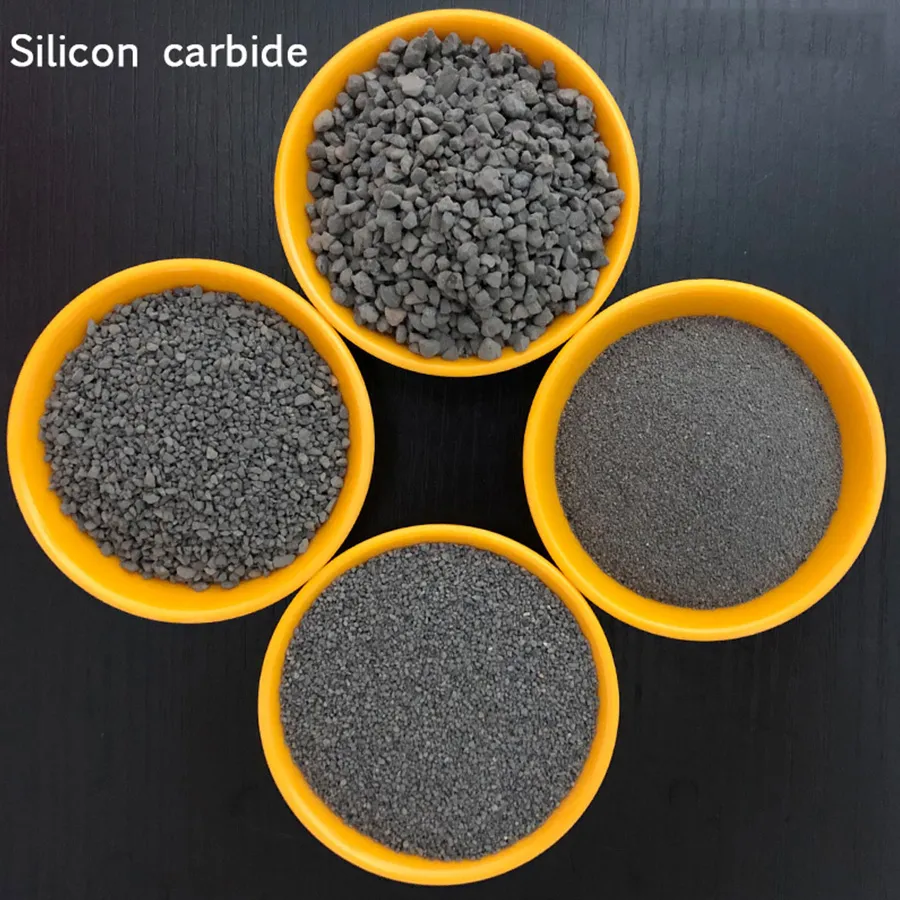

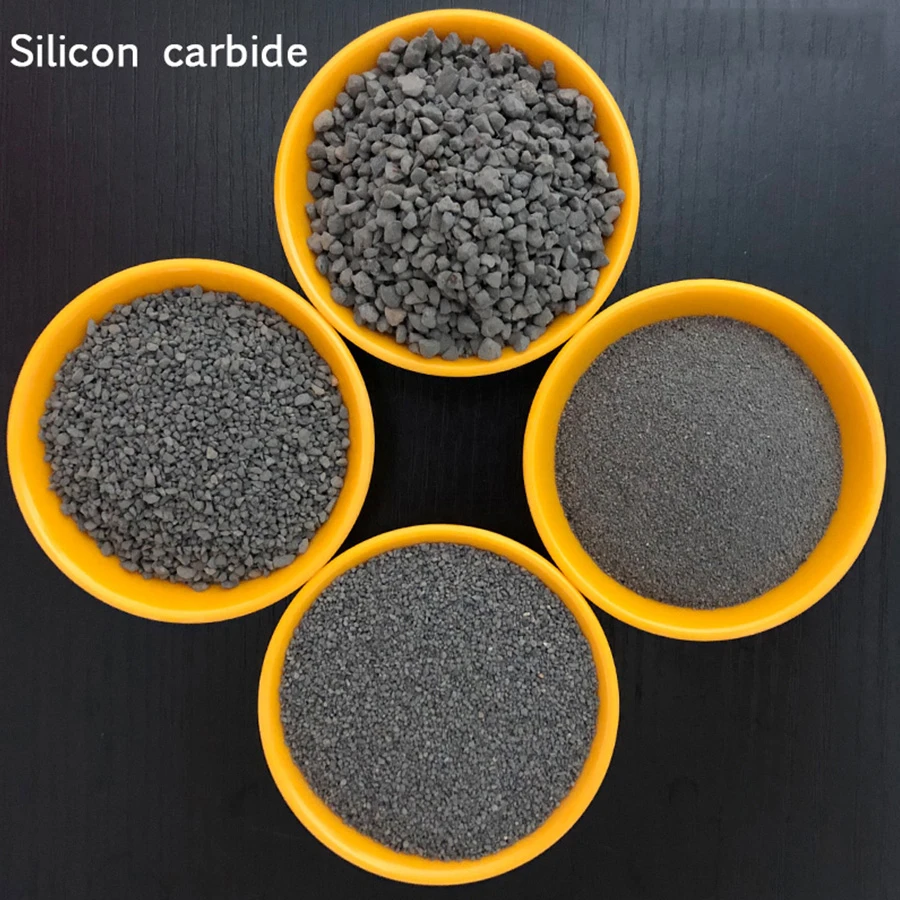

What is Silicon Carbide and Why is it Important in Manufacturing?

Silicon carbide (SiC) is a compound made from silicon and carbon, well-known for its extraordinary hardness, thermal resistance, and durability. These qualities make it an essential material across various manufacturing industries. From high-precision cutting tools to advanced electronics, silicon carbide is driving efficiency and innovation in production.

Its popularity stems from key characteristics—high thermal conductivity, chemical stability, and the ability to withstand mechanical stress. These traits are especially vital in high-temperature environments where performance and longevity are non-negotiable. Products such as alpha silicon carbide and beta silicon carbide serve different functions depending on their crystalline structure, further expanding the versatility of this material.

In modern manufacturing, high-purity silicon carbide supports stringent industrial standards, especially in semiconductors and aerospace engineering. Additionally, carborundum use in abrasive and polishing applications highlights its role in achieving precision results on metal, ceramic, and composite surfaces.

With growing demand for durable, energy-efficient materials, SiC has become increasingly important in power electronics. Silicon carbide power components operate at higher voltages and temperatures than traditional silicon devices, making them crucial for sustainable energy systems and electric vehicles.

Whether you're sourcing silicon carbide for sale in bulk or looking for specialized formulations like silicon carbide black or green silicon carbide, choosing a trusted supplier is essential.

At Baifeng, we provide reliable, high-performance SiC products backed by strict quality control. Reach out to discover the right silicon carbide solution for your application, because durable manufacturing starts with better materials.

Silicon Carbide in Industrial Applications: From Refractories to Abrasives

Thanks to its exceptional mechanical and thermal properties, silicon carbide is widely used across industrial applications—from refractory materials to high-performance abrasives. In the refractory industry, silicon carbide crucibles and carborundum refractory bricks are ideal for furnaces and kilns, withstanding intense heat while maintaining dimensional stability.

In abrasive applications, silicon carbide grit is a top choice due to its extreme hardness and sharp cutting edges. Green silicon carbide and black silicon carbide are widely used in grinding wheels, sandblasting media, and polishing tools. These materials offer superior performance when precision and toughness are needed most.

Beyond basic grit, specialized forms such as crystalline silicon carbide and recrystallized SiC are utilized for their enhanced structure and resistance. Their ability to retain strength at high temperatures makes them invaluable in metallurgical and ceramic industries. Meanwhile, polishing silicon carbide provides a reliable solution for smooth finishes in optical and semiconductor manufacturing.

Different bonding techniques also expand application ranges. Nitride-bonded silicon carbide and oxide-bonded silicon carbide are commonly used in corrosion-resistant linings and structural components, while sintered SiC offers advanced wear resistance.

As industries evolve toward more energy-efficient, long-lasting materials, silicon carbide remains at the forefront of industrial innovation. Whether you're cutting, refining, insulating, or polishing, SiC gets the job done with unmatched durability and precision.

Looking for top-tier silicon carbide products? Baifeng is your reliable partner for everything from abrasive grit to refractory materials. Explore our full product range and competitive silicon carbide price to meet your specific industrial needs.

FAQs about Silicon Carbide

Q1: Is free sampling available before bulk purchase?

A1: Yes, we offer free samples of silicon carbide for quality testing. Whether you're evaluating silicon carbide grit for sandblasting or testing high-purity silicon carbide for advanced manufacturing, Baifeng ensures you get the right material from the start.

Q2: What distinguishes silicon carbide from other industrial abrasives or minerals offered by Baifeng?

A2: Unlike natural volcanic stone or mineral fillers, silicon carbide is a synthetic crystalline material known for its extreme hardness and thermal conductivity. Its Mohs hardness of 9.25 makes it ideal for high-performance cutting, grinding, and polishing, far exceeding standard materials in durability and precision.

Q3: Are there different types of silicon carbide available for specific uses?

A3: Yes, Baifeng offers a full range, including black silicon carbide for general-purpose abrasives, and green silicon carbide for high-purity, high-tech applications such as ceramics and semiconductors. We also supply alpha silicon carbide and beta silicon carbide for advanced sintered and thermal systems.

Q4: How does silicon carbide perform under extreme temperature and chemical conditions?

A4: Silicon carbide is highly resistant to thermal shock and corrosion, making it ideal for refractory linings, crucibles, and kiln furniture. Products like nitride bonded silicon carbide or oxide bonded silicon carbide maintain structural integrity even at temperatures above 1600°C, which standard minerals can't match.

Q5: Can Baifeng’s silicon carbide be used in precision electronics or the semiconductor industry?

A5: Absolutely. Our high-purity silicon carbide and semi-insulating SiC wafers are increasingly used in power electronics, LEDs, and wide-bandgap semiconductor devices. Baifeng supports clients in these sectors with reliable creep-resistant and thermally conductive SiC solutions.

Related Products

The main products include mica,vermiculite,volcanic and stone products.

Related News