- africano

- albanés

- árabe

- bielorruso

- bengalí

- checo

- danés

- Holandés

- Inglés

- finlandés

- Francés

- gallego

- Alemán

- Griego

- hebreo

- húngaro

- indonesio

- irlandés

- italiano

- japonés

- javanés

- kazajo

- Jemer

- Ruandés

- coreano

- Kirguistán

- Mano de obra

- latín

- letón

- lituano

- malayo

- maltés

- mongol

- Myanmar

- noruego

- persa

- Polaco

- portugués

- rumano

- ruso

- serbio

- eslovaco

- Español

- sueco

- Tagalo

- tailandés

- turco

- ucranio

- vietnamita

- galés

The cenosphere price is an essential factor for industries that rely on this lightweight, hollow, and microspherical material for various applications. Cenosphere price can vary depending on factors such as quality, size, quantity, and source, but it remains a cost-effective solution for many industries. Often sourced as a byproduct of coal combustion, cenospheres are prized for their strength-to-weight ratio, heat resistance, and electrical insulation properties. Their competitive price compared to other materials makes them an attractive option for businesses seeking lightweight solutions without compromising performance.

When assessing cenosphere price, it is crucial to consider the specific needs of the application. For example, high-quality cenospheres with precise size distributions may be priced higher but provide superior results in specialized applications such as the aerospace, automotive, and construction industries. On the other hand, lower-grade cenospheres may be more affordable and suitable for general-purpose applications such as in the production of lightweight fillers or for use in paint and coatings. Therefore, understanding the market and comparing prices from various suppliers can help businesses make informed purchasing decisions while optimizing cost-effectiveness.

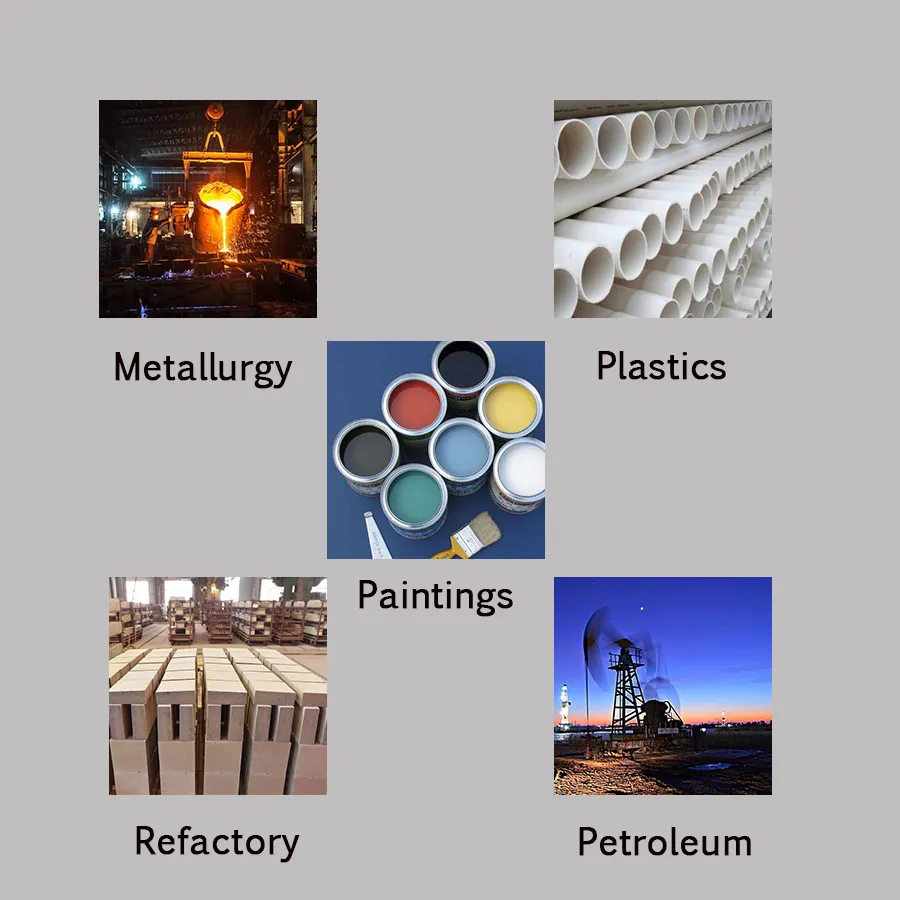

Cenosphere Uses

Cenosphere uses are vast and diverse, and this unique material is increasingly being utilized across various industries. The primary property that makes cenospheres highly desirable is their low density, which allows them to be used as lightweight fillers in numerous products, thereby reducing weight and improving performance. One of the most common cenosphere uses is in the construction industry, where they are added to concrete and other materials to improve workability, reduce weight, and enhance thermal insulation properties. Additionally, cenospheres are used in the production of fire-resistant materials and paints, as they help to improve the strength and fire resistance of these products.

Another significant area of cenosphere uses is in the automotive and aerospace industries, where they are employed to create lightweight composite materials that maintain high strength. By reducing the weight of these components, manufacturers can improve fuel efficiency and overall performance. In the oil and gas industry, cenospheres are also used in the production of drilling fluids, as their ability to withstand high pressures and temperatures makes them ideal for enhancing the efficiency of drilling operations. With applications ranging from industrial to consumer products, cenospheres continue to find new uses as industries seek to reduce weight, enhance performance, and improve sustainability.

Use of Cenosphere

The use of cenosphere in various industries has surged due to its exceptional physical and chemical properties. One of the most critical factors driving the use of cenosphere is its low density and strength-to-weight ratio, which makes it an excellent filler material for lightweight composites. In the construction industry, the use of cenosphere is widespread in lightweight concrete and insulation materials, where it helps reduce the overall weight of the product while still maintaining its strength and durability. By incorporating cenospheres, construction materials can also benefit from enhanced thermal insulation, making them more energy-efficient and cost-effective in the long run.

Beyond construction, the use of cenosphere is increasingly seen in the automotive and aerospace sectors. In these fields, lightweight components are crucial for improving fuel efficiency and reducing overall manufacturing costs. The use of cenosphere in these industries contributes to the creation of advanced composite materials that combine strength and lightweight characteristics. Moreover, the use of cenosphere in paints and coatings has also become more common. Cenosphere-infused coatings offer superior fire resistance, wear resistance, and improved finish quality, making them ideal for industrial and commercial applications. Overall, the use of cenosphere is diverse and continues to expand as industries discover new ways to leverage this remarkable material.

Benefits of Cenosphere in Manufacturing

The inclusion of cenospheres in manufacturing processes offers numerous benefits that contribute to both cost savings and enhanced product performance. One of the most significant advantages of using cenospheres in manufacturing is the material’s lightweight nature, which helps to reduce the overall weight of end products. Whether in concrete, composite materials, or coatings, the incorporation of cenospheres allows manufacturers to achieve the desired strength and durability while keeping the weight of the final product to a minimum. This is particularly beneficial in industries like aerospace, automotive, and construction, where reducing weight is key to improving efficiency and performance.

Another notable benefit of cenospheres is their ability to enhance the thermal and acoustic insulation properties of products. For example, cenospheres are used in lightweight concrete to improve the material's ability to resist heat, which is essential for applications in construction and building materials. In coatings and paints, the use of cenosphere improves fire resistance and durability, ensuring that products are not only lightweight but also long-lasting and safe. Additionally, cenospheres are resistant to high temperatures and pressures, making them ideal for use in challenging environments such as the oil and gas industry. The versatility and wide-ranging benefits of cenospheres make them an indispensable material in modern manufacturing.

Cenosphere Price FAQs

What is the cenosphere price range?

The cenosphere price can vary depending on factors like quality, size, and the intended application. Generally, cenospheres are cost-effective, but higher-grade materials for specialized applications may be more expensive.

What are the main uses of cenosphere?

The cenosphere uses include applications in construction (lightweight concrete), automotive and aerospace (composite materials), oil and gas (drilling fluids), and paints and coatings (enhanced fire resistance).

How is the use of cenosphere beneficial to construction?

The use of cenosphere in construction helps to reduce the weight of concrete and improve thermal insulation properties, making the material more energy-efficient and durable.

Can cenosphere be used in automotive manufacturing?

Yes, the use of cenosphere in automotive manufacturing allows for the creation of lightweight composite materials that improve fuel efficiency and overall performance.

What are the advantages of using cenosphere in manufacturing?

The cenospheres offer benefits such as reduced product weight, improved thermal and acoustic insulation, enhanced fire resistance, and greater durability in high-temperature applications.

Noticias relacionadas